Environment

Development of Eco-Friendly Products

Basic approach

The Mitsuboshi Belting Group recognizes that it is its corporate social responsibility to promote efforts to resolve environmental issues and realize a decarbonized society. Under this recognition, we aim to realize sustainable corporate activities. To this end, we strive to strengthen the development of ecofriendly products and actively work to reduce CO2 emissions in the production process.

- ● : Products that contribute to reducing CO2 emissions

- ● : Products that contribute to the realization of a circular economy

- ● : Products that contribute to the conservation of biodiversity

-

● TG belts for blade pitch drives in wind power generators

Power transmission belts are used to adjust the pitch of blade angles in wind power generators. We will respond to the expanding demand for wind power generation by developing functions for wind power generators to meet customer requirements in terms of power generation capacity, the installation environment, and other conditions.

-

● Low friction loss belts / TG belts in oil

Low friction loss belts and timing belts in oil, developed for automobile internal combustion engines, are effective in improving fuel economy. By providing power transmission belts with high efficiency and low energy loss, we contribute to reducing exhaust gas and CO2 emissions. -

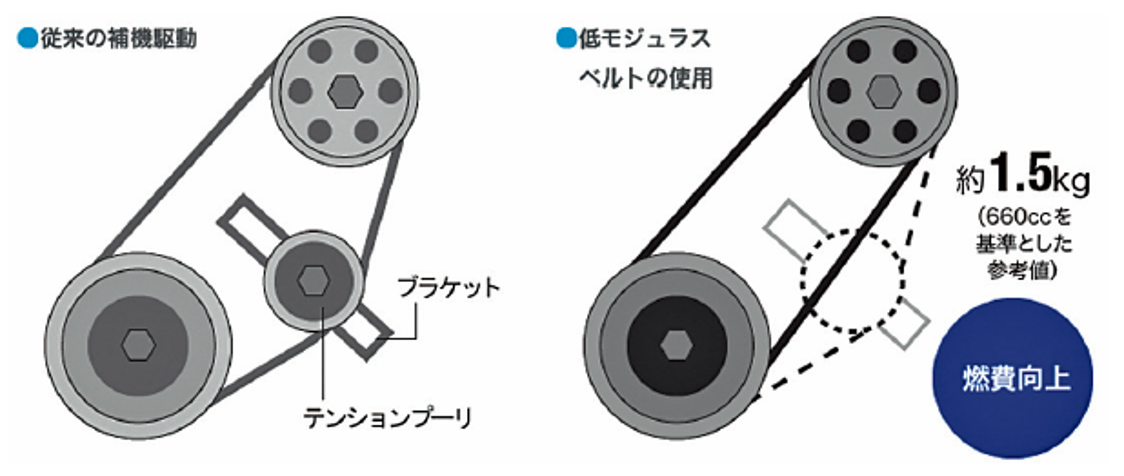

● “StarFit™” low modulus belts for automobiles

The adoption of StarFit™ low modulus belts for automobiles eliminates the need to adjust tension. Since no tension pulleys or brackets are required, the system weight is reduced by approximately 1.5 kg, contributing to improved fuel economy. -

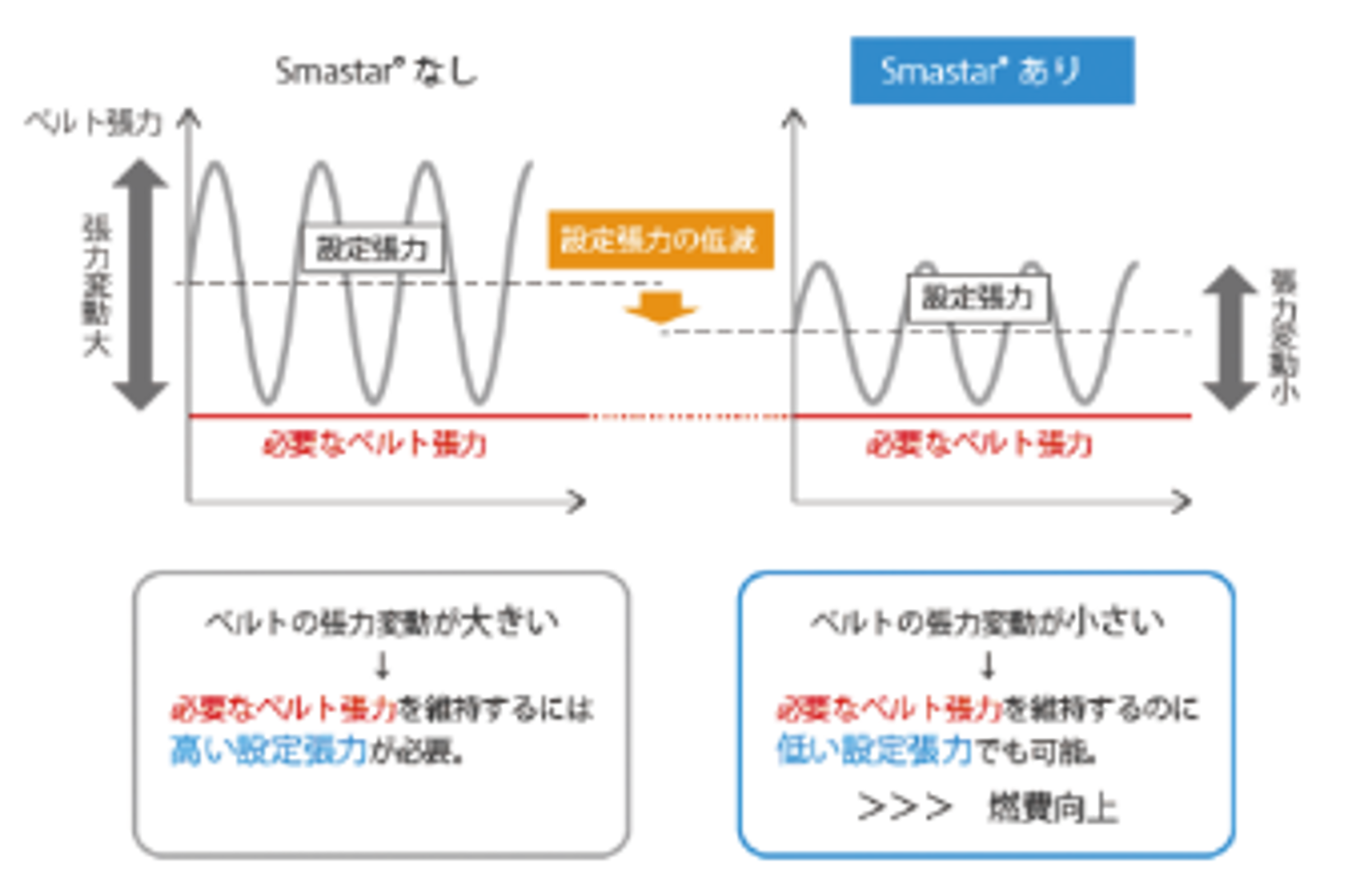

● “Smastar™ ” alternator pulleys for automobiles

With the introduction of technologies for improving fuel economy, such as an idling stop system, rotational fluctuations of the engine are increasing. Smastar™ damper pulleys for alternators, which have been developed to absorb belt tension fluctuations, can lower the tension setting, thereby contributing to suppressing belt noise, increasing belt service life, and further improving fuel economy.

-

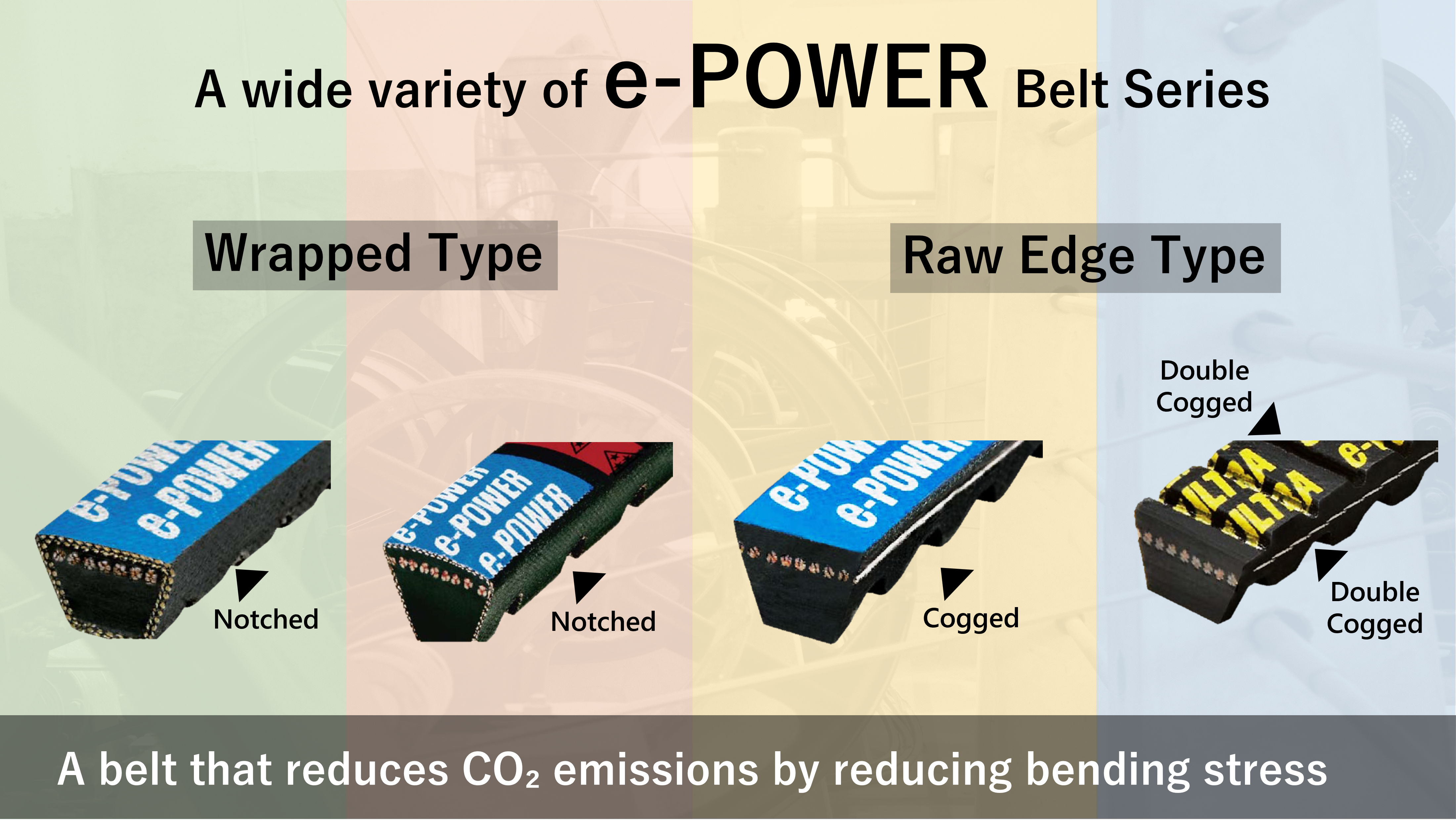

● “e-POWER™ ” energy-saving belts

By adopting a special shape, this environmentally friendly belt reduces bending stress, which is the largest cause of power loss, and enhances energy saving effects. By simply replacing the conventional belt with e-POWER, you can reduce power consumption of machinery and equipment and reduce CO2 emissions. -

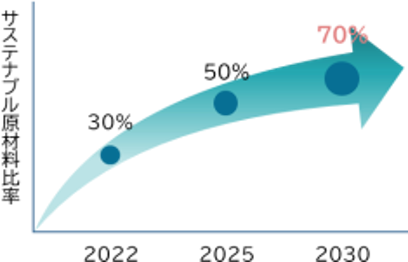

● Power transmission belts with a higher proportion of sustainable raw materials

These are next-generation power transmission belts that reduce the proportion of petroleum-derived raw materials and increase the proportion of sustainable materials, such as biomass and recycled materials. As of 2022, we have achieved a sustainable raw material ratio of 32.7%. We aim to increase the ratio to 50% by 2025 and 70% by 2030. -

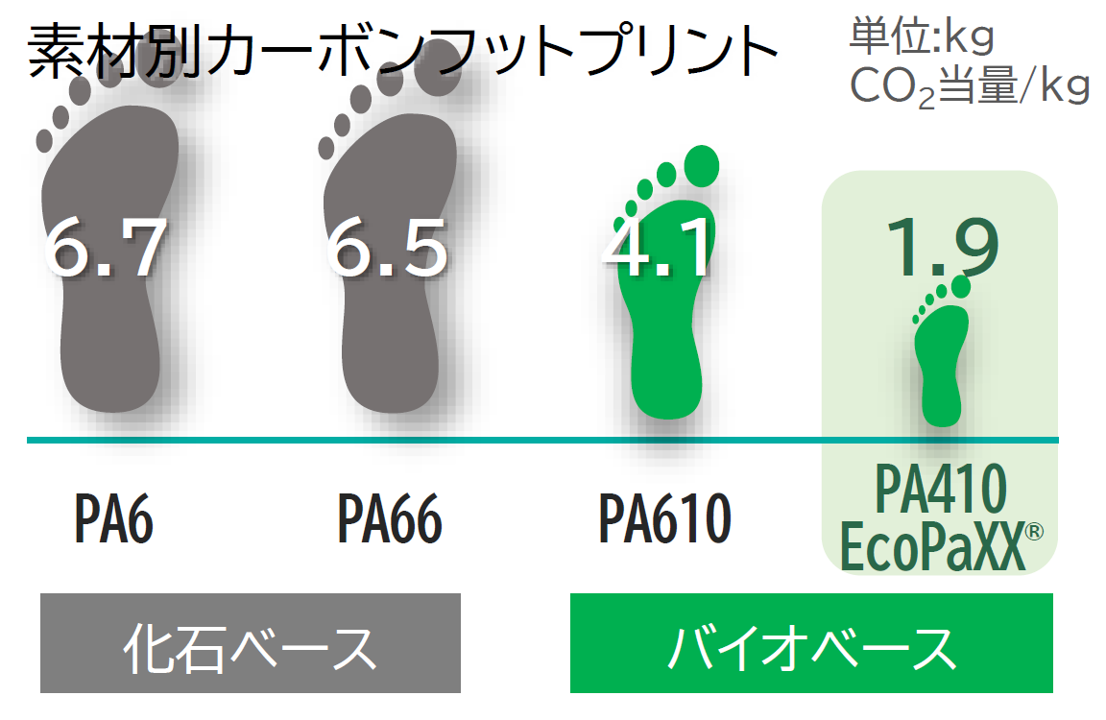

● Plant-derived high-performance nylon material “PA410”

PA410 (EcoPaXX®) is a resin material that uses castor oil derived from castor beans for 70% of its raw materials, reducing the proportion of petroleum-derived raw materials. It has the lowest carbon footprint compared to other polyamides and can contribute to the realization of a decarbonized society. -

● “Water-shielding sheets” from the Building & Construction Materials Division

Water-shielding sheets, including installation services, provided by the Building & Construction Materials Division, contribute to preventing contamination of public water areas and groundwater by leachate from final disposal sites. -

●Contributing to biodiversity conservation

The use of biotopes is promoted at educational institutions across Japan as places for learning, and new ecosystems for animals and plants are created by using water-shielding sheets provided by the Building & Construction Materials Division. We have so far provided water-shielding sheets free of charge to more than 100 educational facilities in Kobe City to cooperate in creating biotopes.