Environment

Initiatives for Water Resources Conservation

Basic approach

Recognizing environmental conservation as one of its important management issues, the Mitsuboshi Belting Group has been committed to water resources conservation.

The initiatives for water resource conservation that we are undertaking are closely related to our initiatives to address climate change caused by global warming. Water is an essential resource for our survival. However, despite its importance, water is being depleted and polluted, seriously affecting our social lives and economic activities, as well as the natural environment.

We are deeply aware of the impact of water depletion and pollution on society and will strive to conserve water resources in our business activities.

Strategy

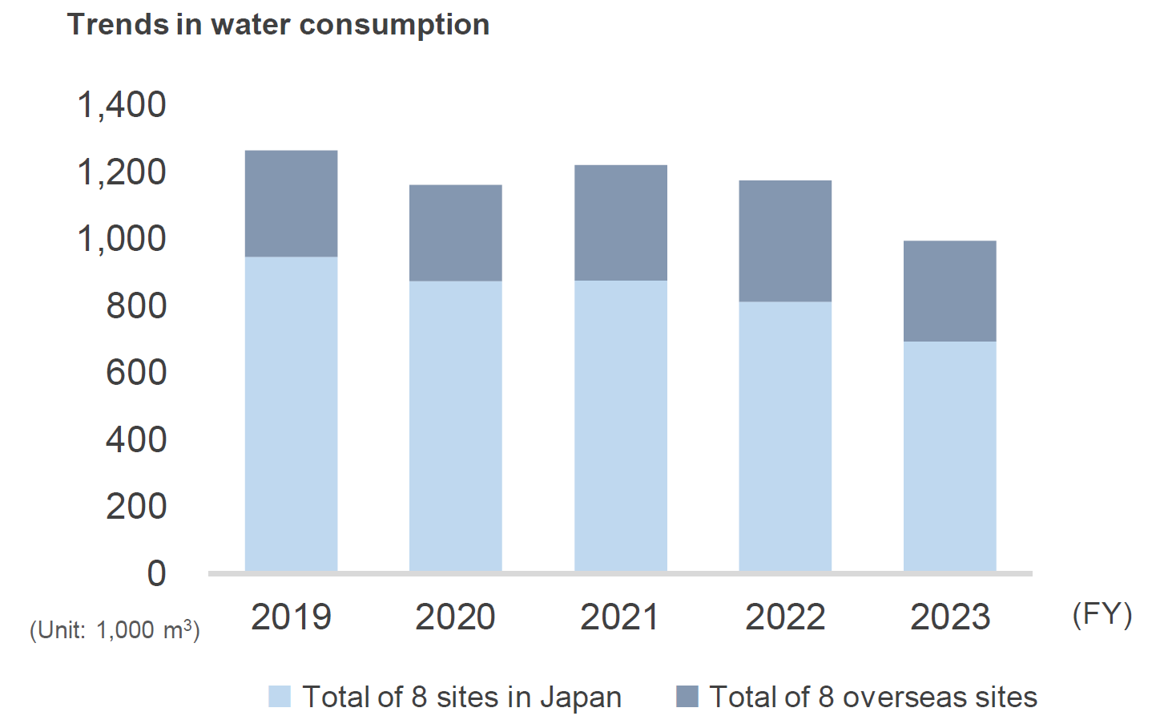

In Japan, where tap water can be used as drinking water and is available at low cost, awareness of water resource conservation tends to fade easily. In fact, Mitsuboshi Belting Group’s production sites in Japan use approximately 2.5 times as much water as its overseas production sites, even though the production volume of transmission belts (main product) at Japanese production sites is only one-third of that of overseas production sites (as of FY2023, see the chart below).

However, it is by no means the case that Japan is free from water problems. Droughts occur in some places in Japan every year. Meanwhile, looking overseas, the heat wave and drought that hit Europe in 2022 had a major negative impact on agricultural production and also affected electricity supply due to a rise in the temperature of the cooling water at nuclear power plants.

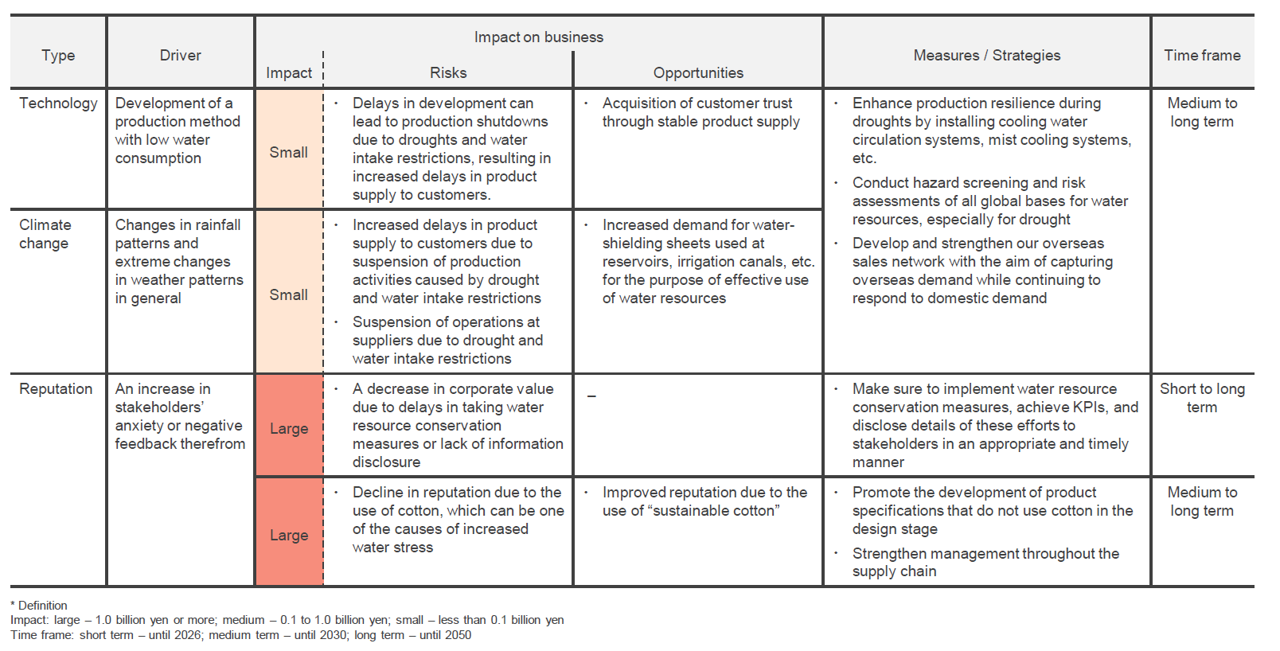

In light of this current situation, we identified risks and opportunities related to water resources conservation and assessed their impact on the Mitsuboshi Belting Group’s business activities, and based on the assessment results, we developed strategies and targets.

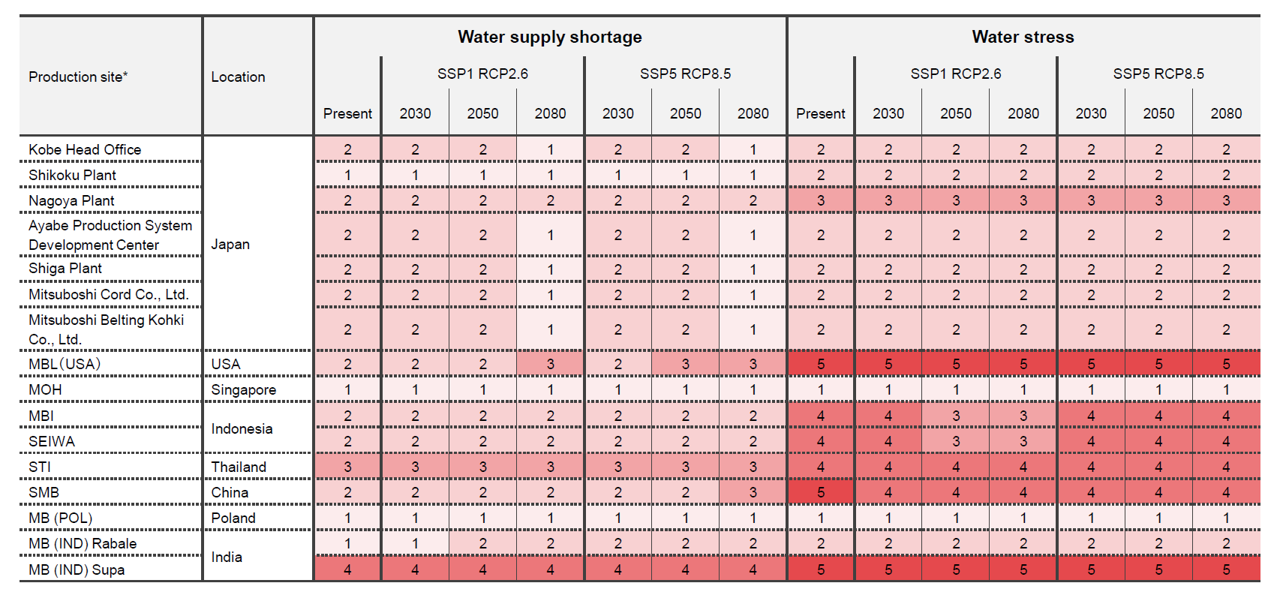

We analyzed and assessed the risks of “water supply shortage” and “water stress” at each production site of the Mitsuboshi Belting Group.

Since water supply shortage risk and water stress risk vary depending on the location of each production site, we obtained information on the current and future water supply shortage risk from the World Resource Institute (WRI)’s Aqueduct Water Risk Atlas. We then assessed each production site’s water supply shortage risk in 2030, 2050 and 2080 under SSP1 RCP2.6 and SSP5 RCP8.5 scenarios and assigned a risk rating to each site on a five-point scale from 1 (low) to 5 (high).

- * Abbreviations for overseas sites in the table

- MBL(USA) : MBL(USA) CORPORATION

- MOH : MITSUBOSHI OVERSEAS HEADQUARTERS PRIVATE LIMITED

- MBI : PT.MITSUBOSHI BELTING INDONESIA

- SEIWA : PT.SEIWA INDONESIA

- STI : STARS TECHNOLOGIES INDUSTRIAL LIMITED

- SMB : SUZHOU MITSUBOSHI BELTINGCO.,LTD.

- MB(POL) : MITSUBOSHI POLAND Sp.zo.o.

- MB(IND)Rabale : MITSUBOSHI BELTING-INDIA PRIVATE LIMITED (RabalePlant)

- MB(IND)Supa : MITSUBOSHI BELTING-INDIA PRIVATE LIMITED (SupaPlant)

We have concluded that the water supply shortage risk at the seven production sites in Japan will be hardly affected by climate change and that the risk will remain at the current low level (Level 1 -2) until the end of the century. The water supply shortage risk at the nine overseas production sites is slightly higher (Level 1 -4) than that at the sites in Japan, but various measures have already been taken, such as installation of cooling water circulation systems and mist cooling systems, and stable operations have been maintained. From the analysis results that the water supply shortage risk will not change significantly from the current level until the end of the century, although we will proceed with the installation of cooling water circulation systems and mist cooling systems, we do not see an immediate need to take action.

As with the water supply shortage risk, the water stress risk at the seven production sites in Japan will be hardly affected by climate change, and the water stress risk will remain at the current low level (Level 2 -3) until the end of the century. As for the nine overseas production sites, one production site in India, one in China and one in the USA are at the highest risk level of 5, while two production sites in Indonesia and one in Thailand are at a fairly high risk level of 4. This situation is expected to continue until the end of the century. The main causes of the worsening water stress risk are said to be the social environment of the region, such as population growth, climate change, and water conflicts, andwehave set water consumption reduction as a basic measure to address water stress and intend to take timely and appropriate measures for each region by properly monitoring and evaluating changesinthe social environment of each region.

Furthermore, as a result of extending the scope of the water stress risk survey to the entire supplier chain, we found that aproduction region of cotton, one of the raw materials we use, and a high water-stressed region overlap in northwestern India. The current water stress in this region is at the highest level of 5 and isnot expected to improve in the future. Growing cotton in high water-stressed regions poses problems not only in terms of water consumption but also in terms of environmental pollution caused bypesticides. Therefore, in the future, we plan to clearly define the implementation of water resources conservation activities in our procurement guidelines, etc., and promote the switch to sustainable cotton and other sustainable materials throughout our supply chain.

As a result of identifying risks and opportunities and assessing their impacts, we have concluded that water supply shortages due to climate change and increased water stress caused by changes in the social environment will affect water withdrawal in the Group’s production activities, leading to increased delays in product supply if no measures are taken and to acquisition of customer trust through stable product supply if appropriate measures are taken. Furthermore, the use of cotton produced in high water-stressed regions as a raw material could have a significant negative impact on the Group’s reputation, as does cotton produced through forced labor, posing a risk that could lead to boycotts.

Meanwhile, it is expected that more dams, reservoirs, irrigation canals, etc. will be constructed for irrigation and efficient use of water resources, and demand for our water-shielding sheets to be used at these facilities and their installation services is expected to increase.

The financial impact of the suspension of production activities will be very minor on a consolidated basis due to the functioning of the global complementary production system, but on an individual production site basis, sales are expected to decrease in proportion to the period of suspension.

Although it is difficult to estimate sales of water-shielding sheets used for irrigation projects separately, sales of the construction materials business as a whole, including these sales, increased to 7.307 billion yen in FY2023, up 27.1% from FY2020.

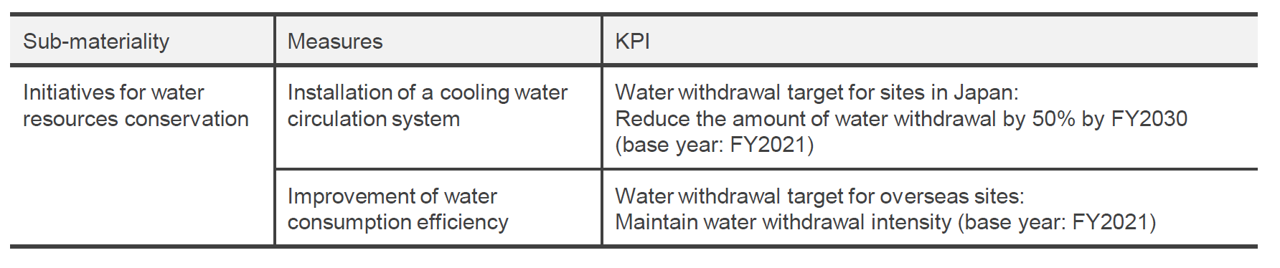

Targets

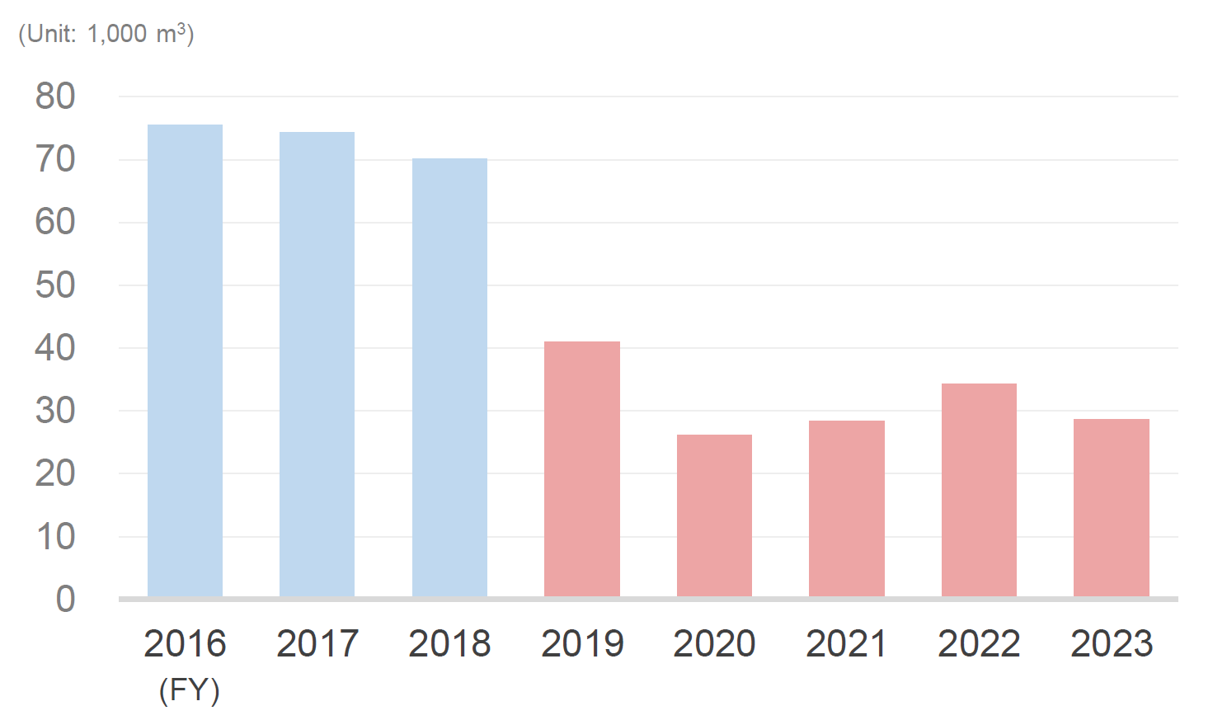

The Mitsuboshi Belting Group has introduced cooling water circulation systems and mist cooling systems to reduce water consumption, mainly at overseas production sites where the water intake environment is harsher than in Japan (see graph below). In the production of rubber products, the “vulcanization” process is essential, which increases the elasticity of rubber through chemical reaction. In this process, sulfur and other chemicals are added to rubber and the mixture is heated to high temperatures (100℃ or higher) to create a chemical reaction. After vulcanization, the rubber is cooled down using water. As described above, vulcanization and post-vulcanization cooling are essential processes for manufacturing rubber products.

Reference - Changes in water consumption at MBL (USA) Corporation

In FY2019, a cooling water circulation system was introduced at our Group’s North American production base, MBL (USA) Corporation. The chart on the right shows changes in water consumption before and after the introduction of the system. Before the introduction of the system, approximately 70,000㎥ of water was used annually, but with the introduction of the system, the annual water consumption was reduced to less than 30,000㎥.

As mentioned, the amount of water used by the Group’s domestic production sites is approximately 2.5 times that of overseas production sites, making it particularly urgent to reduce water consumption at domestic production sites. We have set the following targets and are working to reduce water consumption. At the same time, at our overseas production sites, we will expand the installation of cooling water circulation systems and introduce mist cooling systems to reduce water consumption, with the aim of maintaining water consumption intensity at the same level as FY2021. Through the implementation of these measures, the Group’s water consumption in 2030 is expected to be approximately 900,000㎥ (a 26% reduction compared to FY2021).