Sustainability Strategy

Sustainability Strategy

Approach to sustainability management

The Mitsuboshi Belting Group works to implement ESG management in order to achieve a “trade-on” between corporate value and environmental/social value under the corporate philosophy of “To give attentive consideration to both humanity and nature.”

Setting “contribution to the realization of a sustainable society (improvement of social and economic value)” as one of our goals in the FY2030 “Target Position,” we strive to resolve each ESG issue with a focus on the identified materiality.

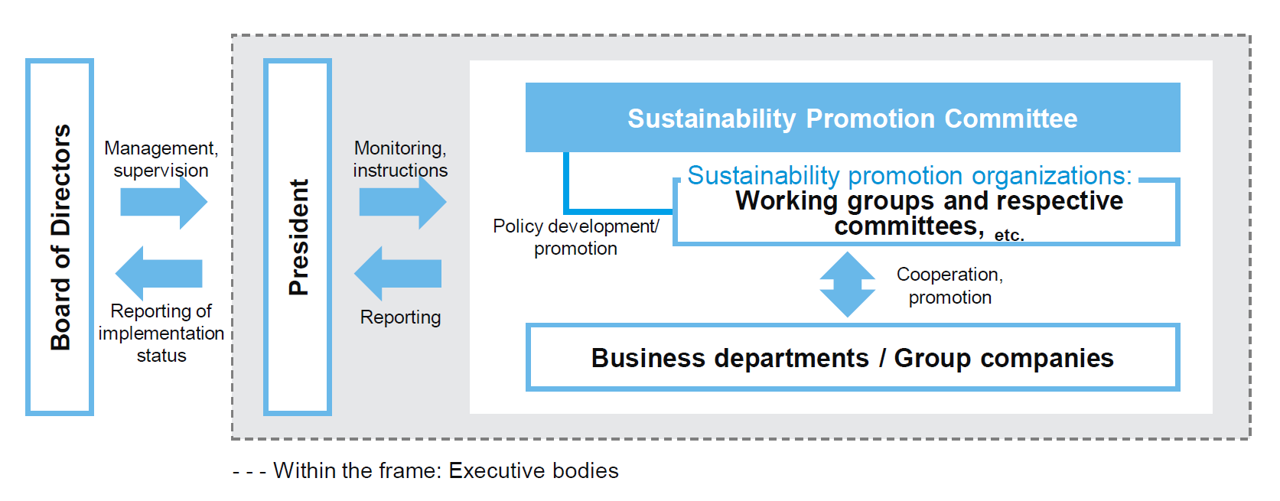

Sustainability management promotion system

In today’s world where companies are expected to play a greater role in addressing environmental and social challenges, with the aim of reconsidering the role and raison d’etre of the Mitsuboshi Belting Group and of quickly and effectively implementing ESG management, we established the Sustainability Promotion Committee, chaired by the President, in April 2022.

A sustainability promotion organization is set up for each identified material issue (the relevant committee/business department or working group that is under the direct control of the Sustainability Promotion Committee serves as a sustainability promotion organization) to address the resolution of each issue and manage KPIs. The progress of implementation is reported to the Sustainability Promotion Committee, which monitors, provides instructions on, judges and evaluates it. The activities of the Sustainability Promotion Committee are reported to the Board of Directors as necessary, which makes final decisions and supervises the sustainability-related activities of the executive bodies.

- Chairperson : President

- Members : Directors (4 persons), Executive Officers (5 persons), General Manager class (1 person)

- Observer : Corporate Auditor (1 person)

- Secretariat : Sustainability Promotion Division

- Meeting frequency : Once a month (11 meetings held in FY2023)

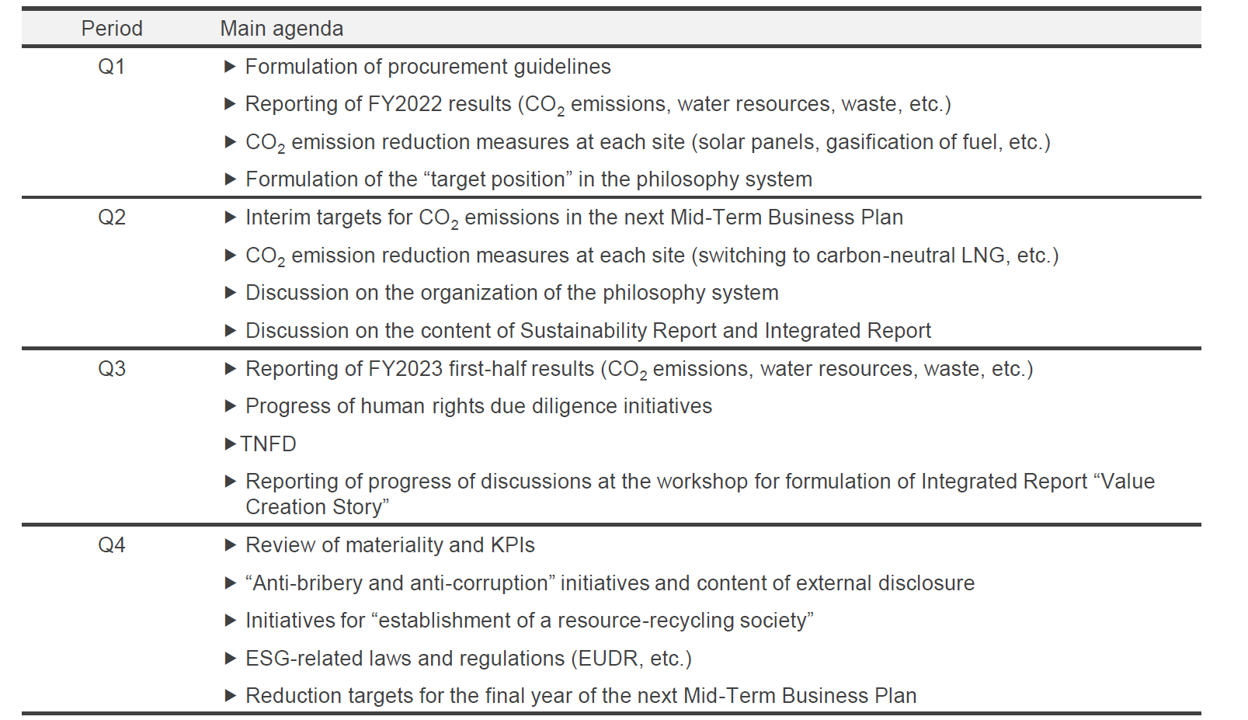

- Content of deliberation :

- Formulation of Group-wide strategies to address sustainability issues, supervision of the progress, and provision of advice

- Discussion on the status of efforts to address each material issue

- Identification of sustainability issues to be deliberated by the Board of Directors and reporting to the Board of Directors

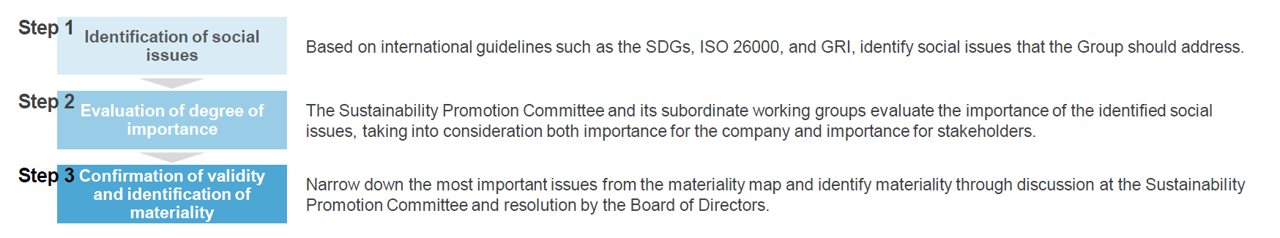

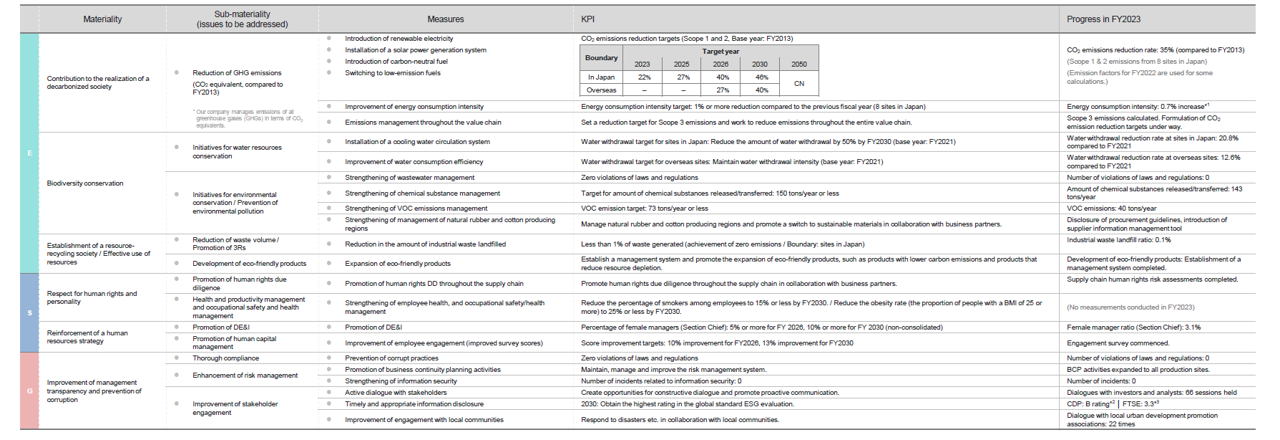

Regarding the resolution of environmental and social issues as a prerequisite for corporate activities, the Mitsuboshi Belting Group has identified material issues (materiality) that the Group should address in order to contribute to the realization of a sustainable society, and has set KPIs for each measure to be implemented.

| Materiality | Sub-materiality (issues to be addressed) |

Measures | KPI | Progress in FY2023 | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

E |

Contribution to the realization of a decarbonized society |

|

|

CO2 emissions reduction targets (Scope 1 and 2, Base year: FY2013)

|

CO2 emissions reduction rate: 35% (compared to FY2013) (Scope 1 & 2 emissions from 8 sites in Japan) (Emission factors for FY2022 are used for some calculations.) |

||||||||||||||||||||||

|

Energy consumption intensity target: 1% or more reduction compared to the previous fiscal year (8 sites in Japan) | Energy consumption intensity: 0.7% increase※1 | |||||||||||||||||||||||||

|

Set a reduction target for Scope 3 emissions and work to reduce emissions throughout the entire value chain | Scope 3 emissions calculated. Formulation of CO2 emission reduction targets under way. |

|||||||||||||||||||||||||

| Biodiversity conservation |

|

|

Water withdrawal target for sites in Japan: Reduce the amount of water withdrawal by 50% by FY2030 (base year: FY2021) | Water withdrawal reduction rate at sites in Japan: 20.8% compared to FY2021 |

|||||||||||||||||||||||

|

Water withdrawal target for overseas sites: Maintain water withdrawal intensity (base year: FY2021) | Water withdrawal reduction rate at overseas sites: 12.6% compared to FY2021 |

|||||||||||||||||||||||||

|

|

Zero violations of laws and regulations | Number of violations of laws and regulations: 0 | ||||||||||||||||||||||||

|

Target for amount of chemical substances released/transferred: 150 tons/year or less | Amount of chemical substances released/transferred: 143 tons/year |

|||||||||||||||||||||||||

|

VOC emission target: 73 tons/year or less | VOC emissions: 40 tons/year | |||||||||||||||||||||||||

|

Manage natural rubber and cotton producing regions and promote a switch to sustainable materials in collaboration with business partners. | Disclosure of procurement guidelines, introduction of supplier information management tool |

|||||||||||||||||||||||||

| Establishment of a resourcerecycling society / Effective use of resources |

|

|

Less than 1% of waste generated (achievement of zero emissions / Boundary: sites in Japan) | Industrial waste landfill ratio: 0.1% | |||||||||||||||||||||||

|

|

Establish a management system and promote the expansion of eco-friendly products, such as products with lower carbon emissions and products that reduce resource depletion. |

Development of eco-friendly products: Establishment of a management system completed. |

||||||||||||||||||||||||

| S | Respect for human rights and personality |

|

|

Promote human rights due diligence throughout the supply chain in collaboration with business partners. | Supply chain human rights risk assessments completed. | ||||||||||||||||||||||

|

|

Reduce the percentage of smokers among employees to 15% or less by FY2030. / Reduce the obesity rate (the proportion of people with a BMI of 25 or more) to 25% or less by FY2030. |

(No measurements conducted in FY2023) | ||||||||||||||||||||||||

| Reinforcement of a human resources strategy |

|

|

Percentage of female managers (Section Chief): 5% or more for FY 2026, 10% or more for FY 2030 (non-consolidated) | Female manager ratio (Section Chief): 3.1% | |||||||||||||||||||||||

|

|

Score improvement targets: 10% improvement for FY2026, 13% improvement for FY2030 | Engagement survey commenced. | ||||||||||||||||||||||||

| G | Improvement of management transparency and prevention of corruption |

|

|

Zero violations of laws and regulations | Number of violations of laws and regulations: 0 | ||||||||||||||||||||||

|

|

Maintain, manage and improve the risk management system. | BCP activities expanded to all production sites. | ||||||||||||||||||||||||

|

Number of incidents related to information security: 0 | Number of incidents: 0 | |||||||||||||||||||||||||

|

|

Create opportunities for constructive dialogue and promote proactive communication. | Dialogues with investors and analysts: 66 sessions held | ||||||||||||||||||||||||

|

2030: Obtain the highest rating in the global standard ESG evaluation. | CDP: B rating ※2 │ FTSE : 3.3 ※3 | |||||||||||||||||||||||||

|

Respond to disasters etc. in collaboration with local communities. | Dialogue with local urban development promotion associations: 22 times |

|||||||||||||||||||||||||

- ※1 Boundary: 8 sites in Japan Energy intensity = total energy consumption / raw material consumption

- ※2 Score announced in February 2024

- ※3 Score announced in June 2024