Social

Value Chain Management

Value Chain Management (2) Quality

Thoughts on quality

The Mitsuboshi Belting Group is a monozukuri company. We believe that customer “trust” in our products and services is one of the sources of corporate value that will enable our Group in achieving continued sustainable growth.

As part of our quality-related initiatives, we have maintained and improved our quality management system (QMS) in accordance with ISO 9001, and have been expanding its scope to the entire Group. At our automotive industry-related locations, we have in place QMS that comply with the IATF16949 standard for the automotive industry, which has more stringent requirements. The quality-related business activities carried out in accordance with the guidelines set forth in these QMS are based on the Basic Quality Policy established under the Corporate Philosophy and the Management Principle of our Group.

QMS certification status (2022)

-

Mitsuboshi Belting Group Basic Quality Policy

Management Principle:

To contribute to society by supplying goods of high performance, high precision, and high quality.

- "To contribute to society by supplying goods of high performance, high precision, and high quality" means creating and providing products that satisfy customers with their performance, functionality, reliability, etc., and that are useful to society.

- So as to realize this Basic Quality Policy, we will adhere to the following. ① Develop products that satisfy customers.

- ②Enhance and improve Total Quality Management (TQM) and ensure top-level quality in the domestic and international industries.

- ③Engage in work in accordance with established standards.

Mitsuboshi Belting Ltd.

Management system

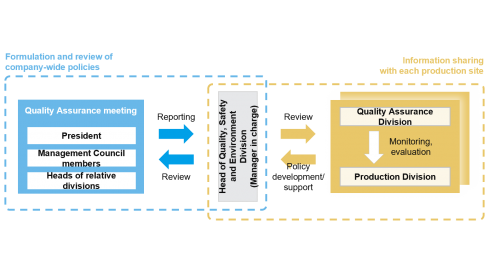

Responsibility and authority regarding quality-related business activities and quality issues rests with the President, and the head of the Quality, Safety, and Environment Division is responsible for managing these activities. The President convenes members of the Management Council and department heads to hold quality assurance meetings, and in the meeting reviews the status of activities reported by the head of the Quality, Safety, and Environment Division, and utilizes the results to improve strategies, policies, and plans. The revised strategies, policies, and plans are communicated to the Quality Assurance Department at each location by the head of the Quality, Safety, and Environment Division, and are developed into policies and plans tailored to each site. The implementation details of the plans are monitored and evaluated by the Quality Assurance Department at each site, compiled monthly into a report, and reported to the head of the Quality, Safety, and Environment Division.

Implementation status

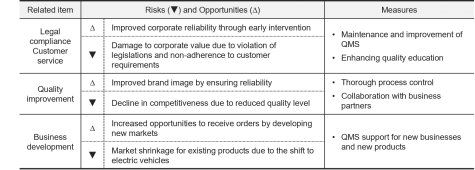

Each item related to quality assurance has been reviewed to identify risks and opportunities it brings to the Mitsuboshi Belting Group business activities, and the results were developed into specific measures. We will continue to further deepen our activities with priority on "Maintenance and improvement of QMS," "Enhancing quality education," and "Thorough process control."

Maintenance and improvement of QMS

In FY2022, we underwent a third-party audit and maintained ISO 9001, IATF16949, or JIS A6008 certification at all audited sites.

Enhancing quality education

The Mitsuboshi Belting Group has been engaged in QC (quality control) circle activities since 1967 as part of the Total Quality Management (TQM), but in recent years, it has become a place for global human resource development and improvement activities. This activity has taken root not only at domestic factories but also at each of the overseas factories. Every fall, the "Mitsuboshi Belting Global QC Circle Tournament" is held, in which presentations on on-site product quality control and work efficiency improvement are made for the purposes of mutual learning. We also actively participate in external QC circle meetings, such as having selected circles make presentations on QC circle national convention sponsored by the Union of Japanese Scientists and Engineers, in an effort to make further improvements.

FY2022, circles selected from all over the Mitsuboshi Belting Group gathered in Singapore, where the Mitsuboshi Belting Global QC Circle Tournament was held. Number of participants were limited so as to minimize the spread of the SARS-Corona virus, but the Tournament was a unifying and meaningful one with active exchanges among the circles. In Japan, QC circle company-wide competitions are held twice a year. Aside from presenting and listening at the venue, the event is streamed online to allow many employees in different locations to participate, resulting in mutual learning that is more active than ever before.

Moreover, we conduct long-term, continuous quality control education to improve knowledge and technology as well as strengthen personnel cultivation. Quality control education begins with training as soon as employees join the company, and is provided in a wide range of areas, including specialized training required for each department and job. We aim to elevate awareness towards quality by having employees obtain specialized knowledge as well as understand and acquire QC-based perspectives and thinking, so that we can align ourselves with our Basic Quality Policy.

Thorough process control

At production sites, production line managers conduct daily workplace patrols as one of the measures to maintain standards compliance, and site managers and other department managers also participate in patrols to prevent them from becoming routine. Although this may seem insignificant, the accumulation of small improvements contributes to complying with standards and maintaining compliance.

Addressing PL lawsuits and recalls

PL lawsuits and recalls damage the "trust" of monozukuri companies, but they can also have a huge financial impact. We prepare for such risks by purchasing an insurance policy that covers the entire Mitsuboshi Belting Group.