Social

Value Chain Management

Basic approach

Stable procurement of superior quality products and services at appropriate prices is a prerequisite for continuing business activities in a sustainable manner, and what serves as the foundation for this prerequisite is the relationship of trust between our Group and our business partners.

As stated in the Mitsuboshi Belting Group Procurement Policy, we are committed to engaging in “fair and impartial procurement activities” and “establishment of a mutually reliable partnerships” with all of our business partners. Through these efforts, we will work to build the types of relationships with our business partners that allow us to co-create new value.

Establishment and disclosure of the Procurement Guidelines

In order for the Mitsuboshi Belting Group to contribute to the realization of a sustainable society while sharing our values with our business partners, we need to deepen our commitment to CSR procurement (compliance, respect for human rights, health and safety, information security, information disclosure, etc.) and green procurement (response to climate change, biodiversity conservation, water security, circular economy, etc.) practices and to strive to resolve various social issues.

In 2023, the Mitsubishi Belting Group formulated the “Procurement Guidelines,” which outline its philosophy regarding procurement and the matters on which it wants to work with its business partners, in line with the ten principles in four areas (human rights, labor, environment, and anti-corruption) established by the UN Global Compact, and disclosed the Guidelines, with the aim of further activating the efforts to realize a sustainable society throughout the entire value chain. We have already received responses in support of our guidelines from business partners accounting for approximately 80% of our raw material procurement value.

In the future, we will identify adverse impacts on such items as human rights, CO2 reduction and biodiversity throughout our value chain, based on the Guidelines, and promote sustainable business practices in cooperation with our business partners.

In particular, with regard to the procurement of natural rubber, there is an urgent need to comply with the EU Deforestation Regulation (EUDR) in Europe. We will work together with our business partners to build a sustainable value chain.

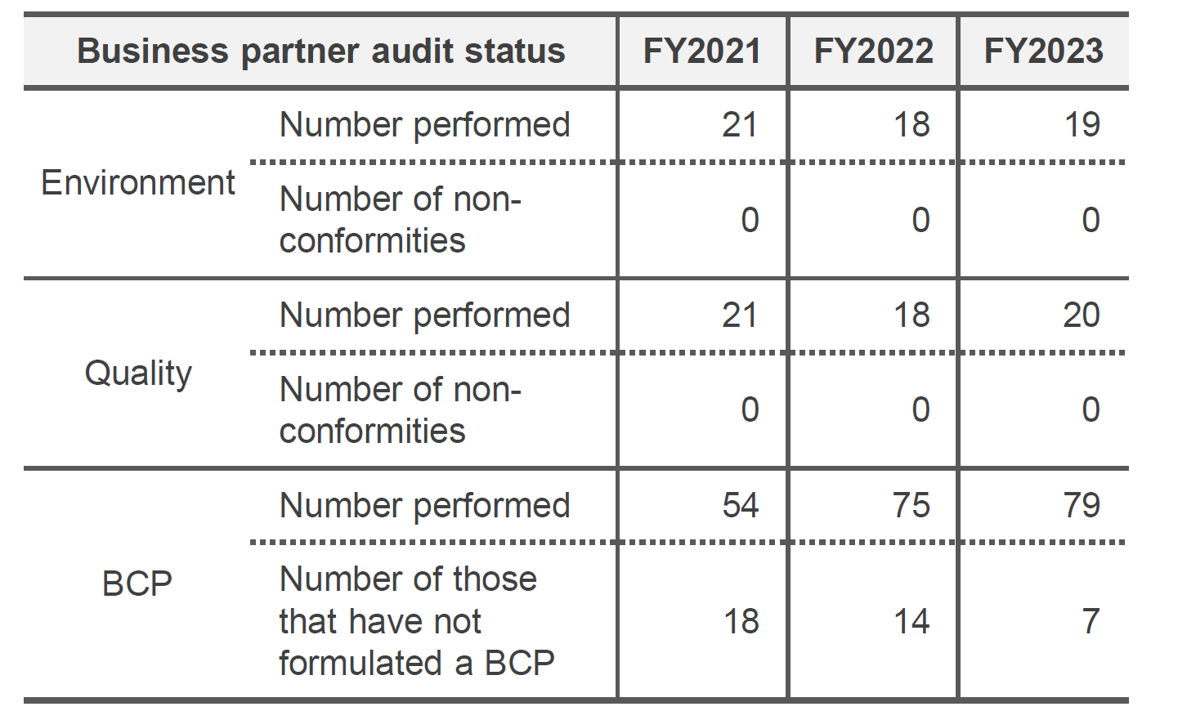

Regarding business partner audits

The Mitsuboshi Belting Group annually conducts two-party audits (in some cases, one-party audits) in accordance with ISO14001 (Environmental Management System (EMS)) or ISO9001/IATF16949 (Quality Management System (QMS)) to monitor, evaluate and improve the status of business partners’ efforts regarding environmental conservation and quality assurance. The business partners to be audited are narrowed down by considering past audit results.

Based on the results of our audits to date, we have determined that our business partners are doing well in terms of environmental conservation and quality assurance, but in the future we should expand the scope of auditing to include not only business partners of the Purchasing Department of the Mitsuboshi Belting Group Head Office but also business partners of affiliated companies of the Group.

In addition, we have been requesting our business partners to formulate and execute Business Continuity Plans since FY2020 as part of our efforts to address climate change, and we confirm the status of their implementation through annual one-party audits. The number of one-party audits is increasing year by year, and in FY2023, all of our 79 business partners cooperated with our audits.

Declaration of Partnership Building

In 2021, Mitsuboshi Belting made the “Declaration of Partnership Building,” advocated by the Ministry of Economy, Trade and Industry, with the aim of creating new added value and conducting fair transactions throughout the supply chain.