-

About Us

-

Investor Relations

- Sustainability

-

Products

- Products TOP

- Field of Application

- Catalog

- Automobile and Motorcycle Transmission Belts and Related Products

- Industrial Power Transmission Belts and Related Products

- Conveyor Belts, Systems and Related Products

- Engineering Plastics Materials and Processed Products

- Waterproofing Materials for Construction and Related Products

- Civil Engineering Water-shielding Materials

- Electronic Materials and Coating Materials

- Other Products

-

Technical Support

- Resources Library

- Video Gallery

Products

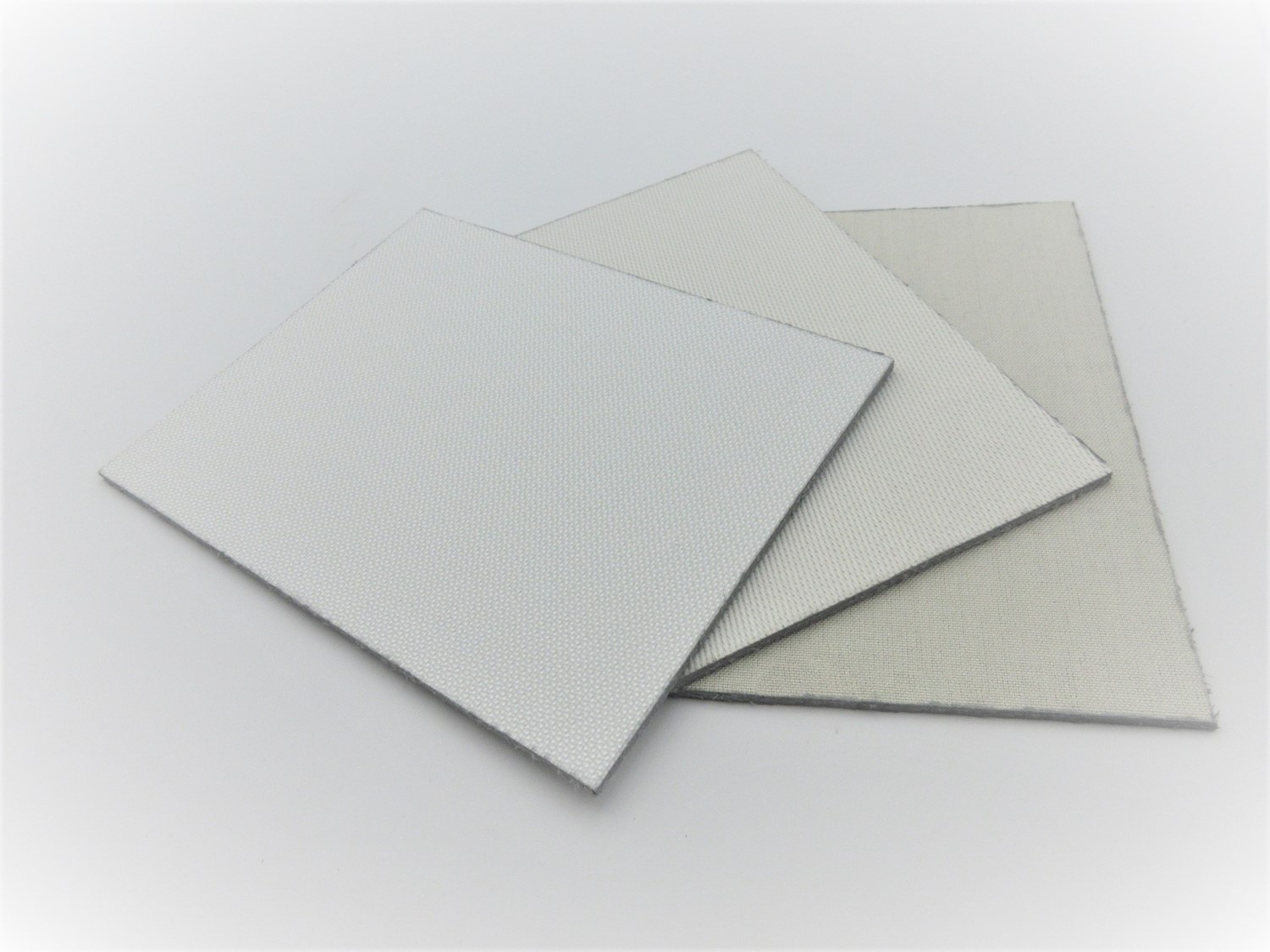

Cushioning material for heat press

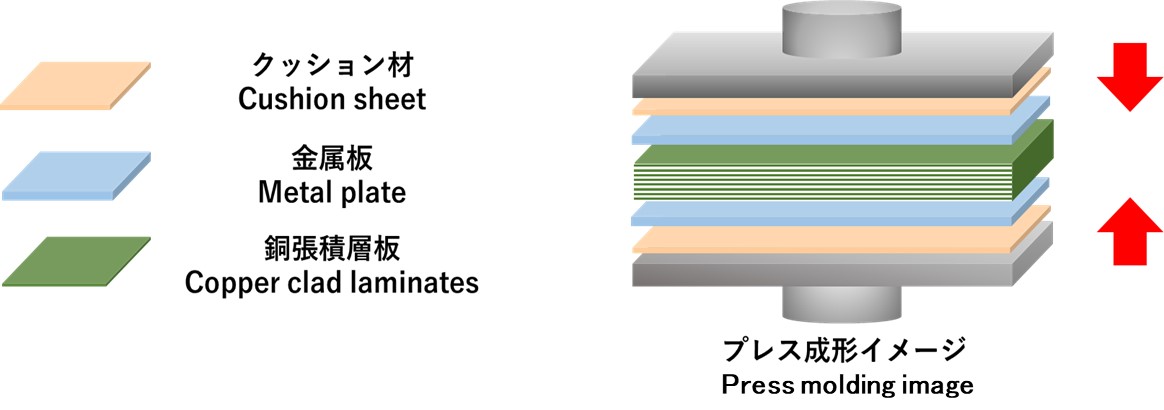

Continuous use type cushioning material used during prepreg and copper foil press forming of copper clad laminates (CCL) and during press forming of printed circuit boards (PCB). It contributes to improved productivity and yield in multi-stage heat press processes and reduction of industrial waste. In addition, it can be applied to press molding where microstrain relaxation of presses is required.

Features

・It can be used continuously at 230°C and has excellent cushioning and durability.

・Rollable type is also available.

・It has been verified to be effective in reducing corrosion of the hot plate (SS400 material) during long-term continuous use.

・Types capable of suction conveyance are also available.

・Maximum size: up to 1300 x 2800 mm, adjustable cushioning (thickness).

structure

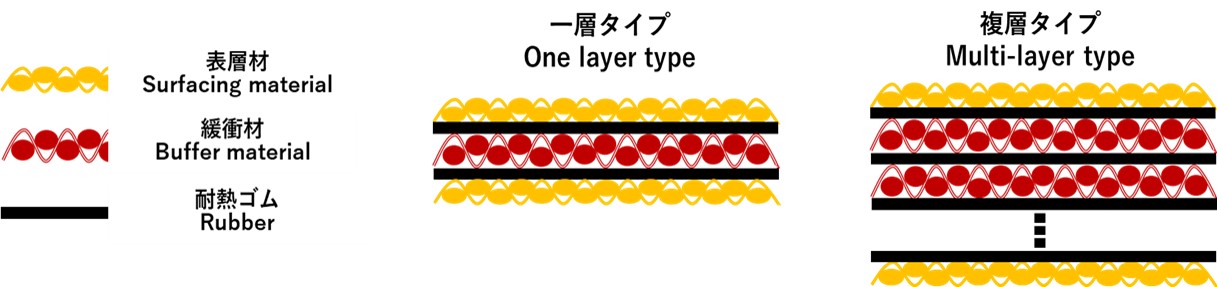

Our cushioning material is a laminate consisting of a surface layer, rubber, and cushioning material. There are "2ply specification" and "3ply specification" depending on the number of layers of cushioning material, and the amount of cushioning can be adjusted by changing the number of layers.

Cushioning and durability

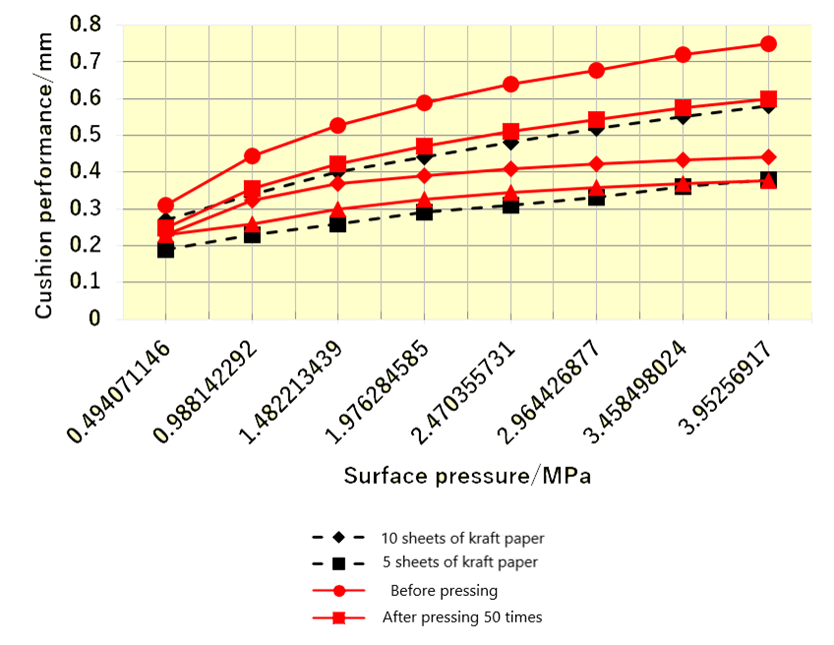

It has superior cushioning properties compared to 10 sheets of kraft paper.

Even after 200 repetitions of holding at a surface pressure of 4 MPa for 1 hour at 230°C, it still has more cushioning than 5 sheets of kraft paper.

_eng.png)