-

About Us

-

Investor Relations

- Sustainability

-

Products

- Products TOP

- Field of Application

- Catalog

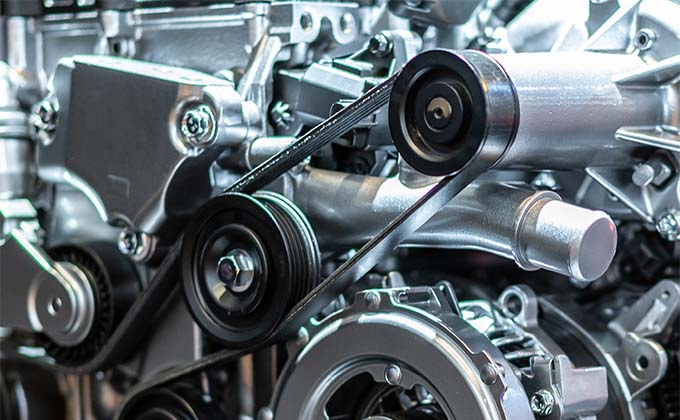

- Automobile and Motorcycle Transmission Belts and Related Products

- Industrial Power Transmission Belts and Related Products

- Conveyor Belts, Systems and Related Products

- Engineering Plastics Materials and Processed Products

- Waterproofing Materials for Construction and Related Products

- Civil Engineering Water-shielding Materials

- Electronic Materials and Coating Materials

- Other Products

-

Technical Support

- Resources Library

- Video Gallery