Technical Support

FAQ

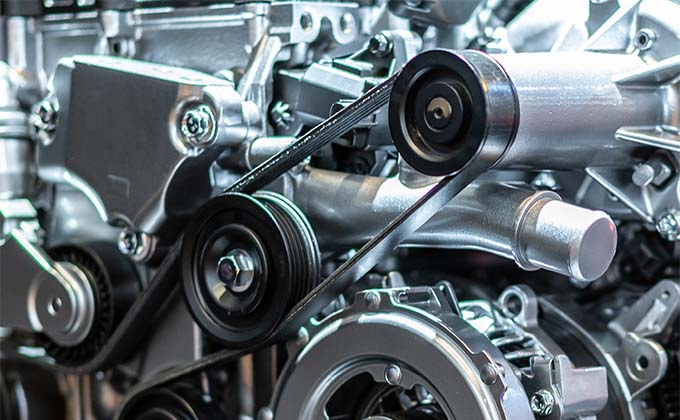

Industrial Power Transmission Belts and Related Products

Q

Are the V-belts RoHS2 compliant?

A

RoHS2 compliant. Please click here for details. If you would like to have a certificate issued, please contact the dealer where you purchased the product or the nearest sales office that handles belts.

Q

When should the V-belt be replaced and what is its life expectancy?

A

We cannot give an answer for the life expectancy, as it depends on the customer's usage conditions. If the belt is cracked or chipped, please replace it immediately.

Q

What is the initial elongation of the V-belt?

A

Initial elongation of V-belts is 1-2% for both standard and red V-belts. The belt must be retensioned within 24 hours of tensioning.

Q

What materials are you using for standard V-belts?

A

Standard V-belts are made of natural rubber-based material. Red Label V-belts and MAXSTAR WEDGE belts use chloroprene rubber.

Q

If I change from a standard V-belt to a red V-belt, will it extend the life of the belt?

A

It depends on the conditions of use. However, if the machine has no problem using a standard V-belt, replacing it with a red V-belt is not expected to significantly improve the life of the machine.

Q

I am using V-belts for multiple hangings, but there is a difference in belt length and the belts are flapping. Is there a better way?

A

V-belts vary in length. If you are concerned about length differences, please specify as matched set.

Q

I am using products from other manufacturers. Can I use the Doctor Tension Type IV to measure tension?

A

Products from other manufacturers can also be measured. Since the standard values for unit weight and unit mass of belts differ depending on the manufacturer, please contact the belt manufacturer you are using for the unit weight.

Q

What materials are you using for standard timing belts?

A

The material of timing belt is below.

【Rubber Belt】Tooth:Chloroprene Rubber Tensile Cord:Glass Code Tooth Fabric:Nylon

【Urethane Belt】Tooth:Polyurethane Tensile Cord:Aramid or Steel wire

Please inquire separately for other MEGA TORQUE series and materials with special specifications.

Q

What is the amount of backlash between the timing belt and pulley?

A

Please inquire separately for backlash values between each belt and standard pulleys. The backlash value we provide is the gap between the belt teeth and pulley teeth under static conditions. Backlashless pulleys are available depending on the tooth profile.

Q

How can I improve positioning accuracy?

A

We suggest to switch to our MEGA TORQUE EX This timing belt was developed to increase positioning accuracy through a special tooth profile.

Q

What is the differnce between a polyurethane and a rubber belt?

A

For normal transmission applications, rubber belts with a wide range of sizes are used. If scattering of rubber powder is a concern,polyurethane belts are preferred, which generate less abrasion powder.

Q

Is the belt compatible with belts from other manufacturers?

A

Timing belt G and timing belt U (MXL, T80, XL, L, H, XH, XXH, etc.) are ISO standard products and are compatible with all companies. Round tooth type products such as SUPER TORQUE series and MEGA TORQUE series are not interchangeable except for some manufacturers.

Q

How shoud I maintain timing belts?

A

Timing belts are maintenance free. The installed tension of the belt will decrease slightly in the first few hours of operation due to the pulleys becoming more familiar with each other. After installation, run the belt for about 1 minute (or 10 rpm for slower speed) to allow it to acclimate, and then tension it at the specified tension. There is no need to re-tension the belt after that.

※Re-tensioning the timing belt may cause poor meshing and shorten the life of the belt.

Q

Can I apply grease to the surface of the timing belt?

A

Although there is no problem if grease gets on the belt, applying grease to the belt is not recommended.

Q

Is it possible to manufacture timing belts in sizes not listed in the catalog?

A

Belts are manufactured using molds.

Sizes not listed in the catalog cannot be manufactured due to lack of molds.

Q

Is there a specific time to replace the timing belt?

A

If the belt is cracked or belt teeth are chipped, replace it immediately. In order to minimize downtime, especially for heavy-duty machines, please include cracks or missing belts in periodic inspections and replace the belt before it is damaged.

Click here for the document.

Q

Can it be used in clean rooms?

A

Rubber timing belts generate dust even in bareback specifications, which generate little dust. When using the product in a clean room, please take measures such as installing covers around the belt.

Q

What is the heat resistance temperature of timing belt?

A

The heat resistance temperature of the standard belt is -30°C to 80°C. Please note, if used outside of room temperature, the life of the product may be shortened. If you require heat resistance for operating temperatures up to 100°C, use a belt with heat-resistant specifications. Please inquire separately for details on heat-resistant specifications.

Q

Can you manufacture belts in widths not shown in the catalog?

A

Basically, the standard widths listed in the catalog are available. If you require a belt width not listed in the catalog, please contact our sales representatives or distributors.

Q

What is the unit mass?

A

Unit weights are listed in the catalog. Please check the catalog.

Click here to download catalog.

Q

How should I measure the belt installation tension?

A

There are two ways to measure belt tension: by deflection load or by sound waves. Use a pencil type tension meter when measuring by deflection load, or use a sonic tension meter Doctor Tension Type IV when measuring by sound waves.

For more information about Dr. Tension Type IV, please click ※MEGA TORQUE GIIP, MEGA TORQUE GⅢ, and Giga Torque GX cannot be measured with deflection load.

Q

Are the timing belts compliant with the RoHS2 directive?

A

RoHS2 compliant. Please click here for details. If you need a certificate, please contact the dealer where you purchased the product or the nearest sales office that handles belts.

Q

What is the difference between MEGA TORQUE GIIP and GIII?

A

Improved materials have greatly increased transmission capacity.

In addition, standard pulleys can now be used for MEGA TORQUE GⅢ.

Q

If a belt does not have a size label on it, but only a part number, how can I buy it?

A

The belts listed in the part numbers are exclusive belts for a specific machine manufacturer (OEM products), so please purchase genuine parts from the machine manufacturer.

Q

The belt circumferential speed is limited to 33 m/sec. What happens if the belt circumferential speed is exceeded?

A

Durability and service life are greatly reduced.

In addition, the dynamic balance of the pulley must be carefully balanced because of the increased noise level.

Q

How should the tension pulley be installed?

A

When installing on the inner side of the belt, install on the loose side during running, close to the large pulley.

The inner tension pulley diameter should be larger than the minimum pulley diameter in the catalog.

For outside installation, the belt bending angle should be 140° or more (160° or more for MEGA TORQUE GⅢ and Giga Torque GX) at a position close to the small pulley.

The outer tension pulley diameter should be at least 20% larger than the minimum pulley diameter in the catalog.

Click here for the document.

Q

What is the transmission efficiency of the timing belt?

A

Transmission efficiency is almost 100%.

However, since the motor shaft is loaded by the belt tension, power loss may occur and the transmission efficiency may be lower than 100%.

Q

What size are the shaft holes for standard pulleys?

A

The minimum shaft hole diameter d (mm) is listed in the pulley dimensions table on the product introduction page of this website.

A pre-hole is machined to allow machining to its minimum shaft hole diameter (H7 tolerance).

Q

What is the material of the standard pulley?

A

The steel material is mainly S25C, but some free-cutting steel is used.

High strength aluminum alloy is A2017. Castings are FC200 equivalent.

Q

Is it possible to purchase only the flange of the standard pulley?

A

Flanges only are not available for purchase.

Q

Does the standard pulley have flanges?

A

Two pieces are attached to pulley shapes A and B. Pulley shape C is provided with 1 piece. Pulley shape W is not provided.

Up to 15 flanges can be attached to each pulley for bar pulleys. Please be sure to specify the number of pieces required when purchasing.

Q

Are standard pulleys surface treated?

A

Standard pulleys are not surface treated, but sintered material pulleys are steam treated.

※Some sizes are not supported.

Q

What types of surface treatments are available?

A

Custom-made pulleys are available with customer-specified surface treatment.

Q

Are there any with a "G" at the beginning of the pulley designation?

A

In the past, G 32S2M0100A was prefixed with "G", but now it is prefixed with "P" to make it easier to distinguish it from the belt. There is no change in the specifications.

Notation of past:G 32S2M0100A

↓

Present notation:P 32S2M0100A

Q

What are the shaft hole diameters min and max listed in the catalog?

A

min=minimum shaft hole diameter

max=maximum shaft hole diameter

Our standard pulleys are shipped with the bottom hole machined. Please use this as a guide when machining by the customer.

Q

Can you manufacture belts with a number of teeth not listed in the catalog?

A

The number of teeth that can be manufactured differs depending on the specifications and shape. Please contact us for details.

Q

Can you manufacture pulleys in materials not listed in the catalog?

A

We can produce pulleys as made-to-order pulleys.

If you provide us with a drawing, we will provide you with a quotation through our distributor.

Q

Are CAD drawings available?

A

It can be downloaded from our website. Please download from here.

Q

How should the flange be installed?

A

There are two types of flange attachment methods: caulking and screw fixing.

For details, please refer to "Flanges" in the timing belt transmission design document.

Click here for the document.

Q

Are backlashless pulleys available?

A

Some tooth shapes are available. Please contact us for details.

Q

Are the timing pulleys RoHS2 compliant?

A

RoHS2 compliant. Please for details. If you would like to have a certificate issued, please contact the dealer where you purchased the product or the nearest sales office.

Q

How can I purchase a belt?

A

We deal through distributors and do not sell directly. Please contact the distributor.

Q

How can I get a catalog?

A

Please contact our distributors or use our catalog request form.

You can also download PDF files from our website.

Q

How should STARROPE and SUPER STARROPE be welded?

A

Heat weld.

Q

What is the proper tension?

A

Proper tension varies depending on the conditions of use. The formulas for calculating proper tension are provided in each catalog. Please check each catalog.

For timing belts and V-belts, please use the "Tension Calculator"

Q

What is the difference between V-belt types A/B/C and LA/LB/LC?

A

LA/LB/LC types are belts for agricultural machinery. These belts are thinner than standard V-belts and Red Label V-belts (A/B/C types) and are designed to withstand reverse bending.

Q

What is the bareback specification of the timing belt?

A

The tooth fabric is specially treated to suppress the scattering of rubber powder.

Q

How do I install the timing belt?

A

Please click here to watch the video for more information.