Technical Support

FAQ

Conveyor Belts, Systems and Related Products

Q

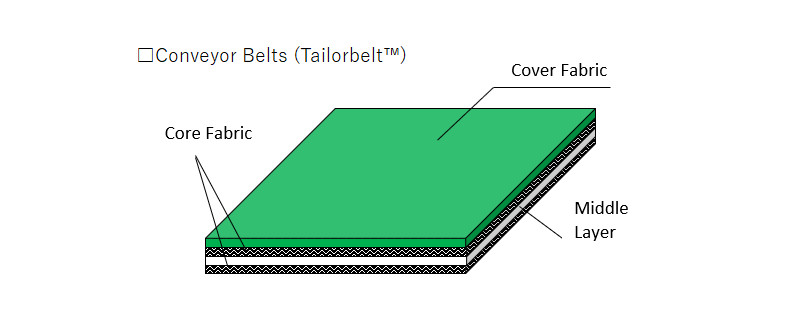

Structure and Names of Conveyor Belts (Tailorbelt™)

A

It consists of a core fabric which is used to support the tension of the belt and a cover fabric that prevents damage to the core fabric.

Q

The length of Conveyor Belts (Tailorbelt™)

A

Conveyor belt joints are made on a flat spot, so they are manufactured with a "center circumference".

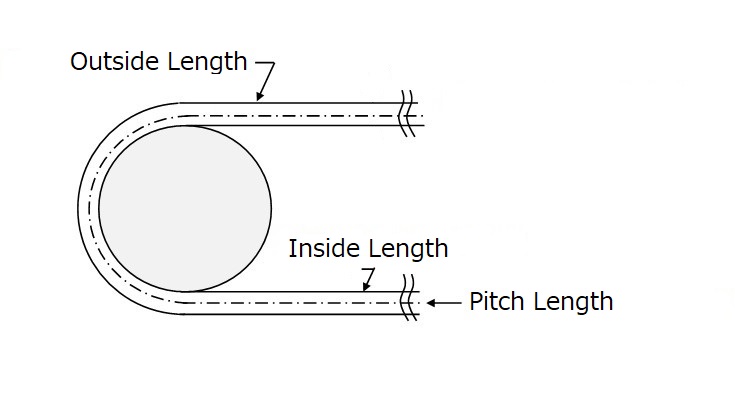

【Fig. 1.the length of the belt】

We are often asked about belt length in terms of "inner circumference". The inner circumference length is the length measured inside the jointed belt, but it cannot be measured exactly due to the thickness of the tape measure and other factors. The same applies to the outer circumference.

Q

Conveyor Belts (Tailorbelt™) length at time of order

A

If there is no special specification, we will manufacture the product with the "center circumference" as above. The "inner circumference" is also converted to the center circumference.

Q

Installation tension of Conveyor Belts (Tailorbelt™)

A

Proper tension is required when installing belts on conveyors. Loose tension will cause the belt to slip, while strong tension will lead to early damage to the joints and damage to the conveyor pulley bearings.

The proper tension must be determined for each condition of use. In practice, it is complicated and difficult to manage the tension of individual belts. We propose a method to control the initial tension by belt elongation.

Tailorbelt®-U,V,P:0.1-0.3% in belt elongation

Tailorbelt®-F(FG type):0.05-0.1% in belt elongation

Tailorbelt®-F(FK type):0.1-0.2% in belt elongation

Q

Installation tension control of Conveyor Belts (Tailorbelt™)

A

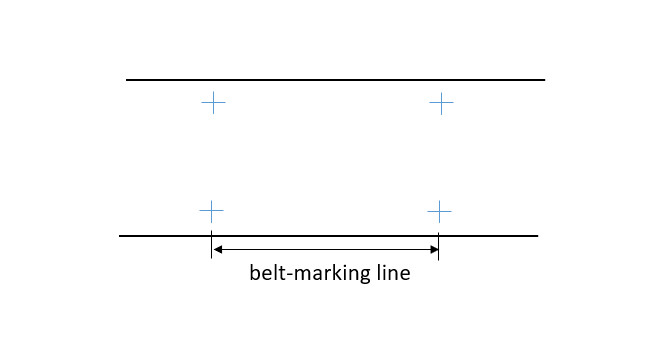

Initial belt tension is controlled by belt elongation. For elongation, before installing the belt on the conveyor, put a marked line (preferably 1000 mm long) in the belt as shown in Fig. 3 to tension the belt.

【Fig. 3.belt-marking line】

【Fig. 3.belt-marking line】

※Avoid areas near joints and mark lines.

※When the belt width is wide, mark lines on the left and right as shown above.

In the case of Tailorbelt™-U

Initial tension (approx.) 0.1-0.3% in belt elongation.

For a 1000 mm marker, tension is applied so that it is 1 to 3 mm。

※The marker line should be measured on a flat area with no bends caused by pulleys or the like.

※Tension should be applied equally to the left and right side.