-

About Us

-

Investor Relations

- Sustainability

-

Products

- Products TOP

- Field of Application

- Catalog

- Automobile and Motorcycle Transmission Belts and Related Products

- Industrial Power Transmission Belts and Related Products

- Conveyor Belts, Systems and Related Products

- Engineering Plastics Materials and Processed Products

- Waterproofing Materials for Construction and Related Products

- Civil Engineering Water-shielding Materials

- Electronic Materials and Coating Materials

- Other Products

-

Technical Support

- Resources Library

- Video Gallery

Products

Resistive Paste

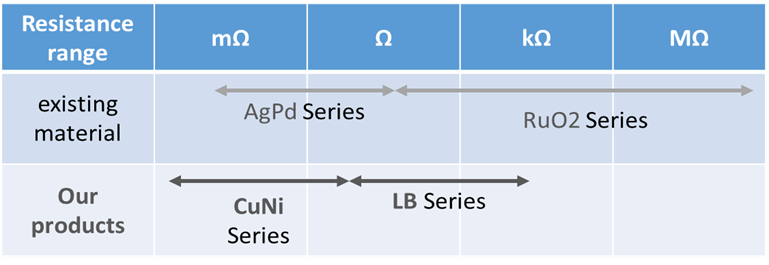

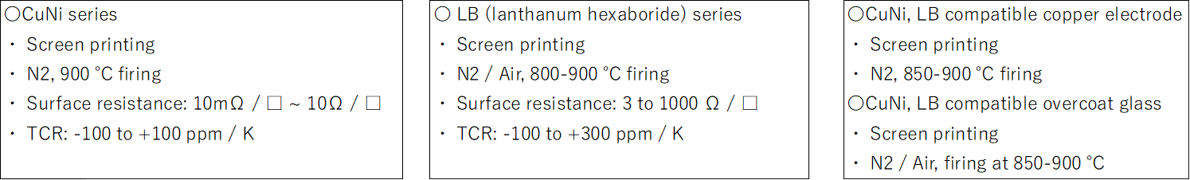

In recent years, there has been a growing demand for resistive components and chip resistors (SMDs) to take measures against sulfurization of Ag electrodes and to improve migration resistance. One of these measures is the use of copper-based conductors. However, ruthenium oxide or Ag/Pd resistive pastes, which are currently mainly used, are unstable when fired in a nitrogen atmosphere because the resistive components and glass components are reduced and altered, resulting in an unstable resistance value. The base metal thick film resistive pastes such as Cu/Ni developed and produced by our company can be fired in a nitrogen atmosphere, so the resistance value will not become unstable. In particular, we are capable of producing pastes for ultra-low resistance areas. We also offer paste printing on substrates.(Thick film circuit board)

Physical Properties

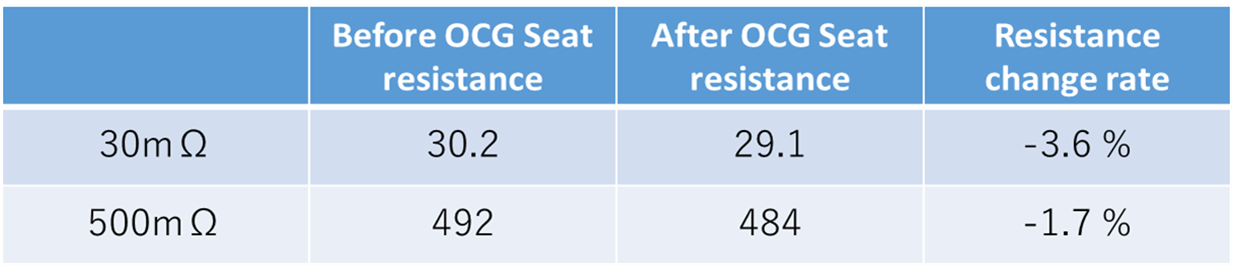

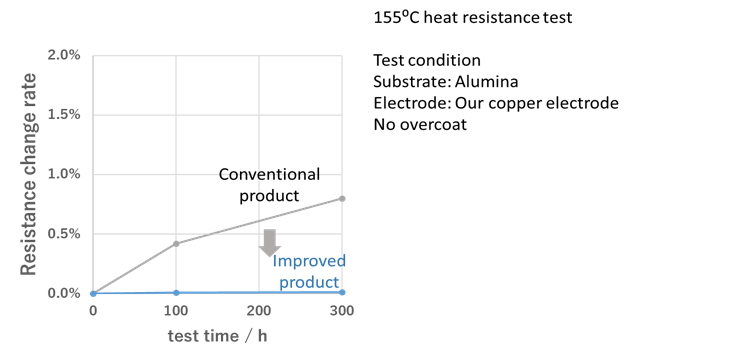

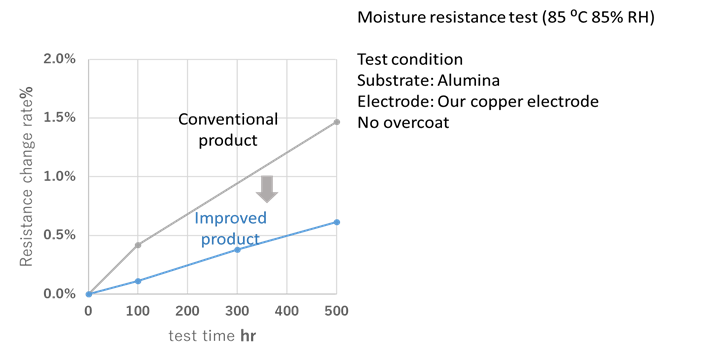

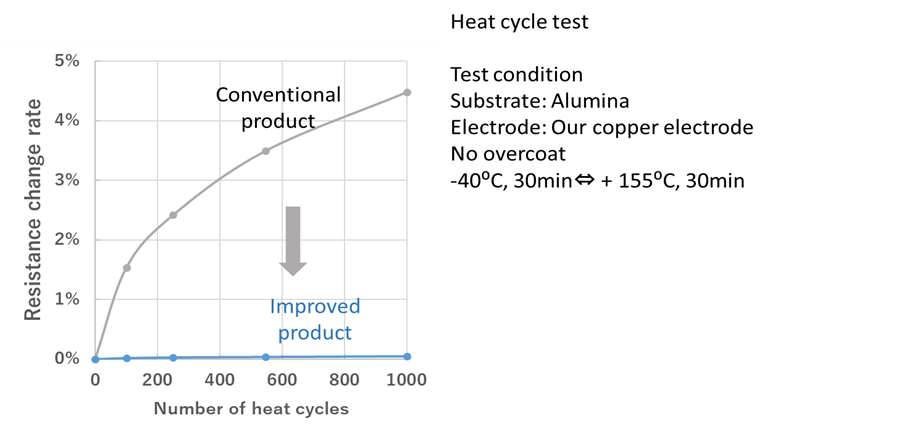

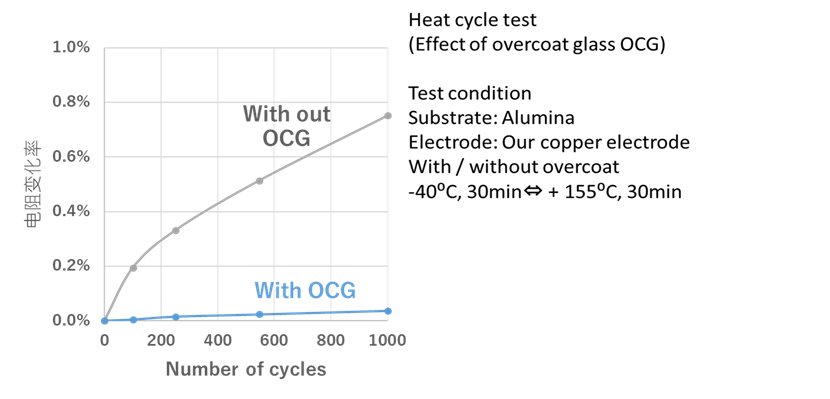

Although reliability is generally a concern with copper-based materials, resistance changes can be kept very small. Our overcoat glass has a small change in resistance before and after firing, further improving reliability. It prevents the diffusion of metallic components from resistive elements and copper conductors into the glass and suppresses the resistance change before and after firing.

Features

・It can be sintered in a nitrogen atmosphere and can be used with substrates with copper electrodes and wiring.

・Low-resistance Cu/Ni paste is ideal for current sensing and power management resistor chips.

It also has low TCR and can meet ±100ppm chip resistor quality requirements.

・Since it is base metal based, it is less expensive than Ag/Pd alloy or ruthenium oxide based resistor materials.

・Contains no environmentally hazardous substances such as lead.

Achievement・Assumed Applications

・Chip resistors for current sensing

・Chip resistors for power management

・Ceramic heaters

・Ceramic circuit boards with resistive elements (thick film resistive paste)

specification

Precautions

・Handling precautions should be in accordance with the Material Safety Data Sheet (SDS) for each product.

Remarks

・A nitrogen displacement furnace is required for firing.

・We also offer contract firing services in development and production, so please consult with us.

・These results are based on the use of our copper paste for the electrode and our glass paste for the protective film.

・We recommend the use of our products for resistors, copper paste, and glass paste because of matching.

・"CUX" is a trademark for Mitsuboshi Belting's copper-related products.

_eng.png)