Technical Support

FAQ

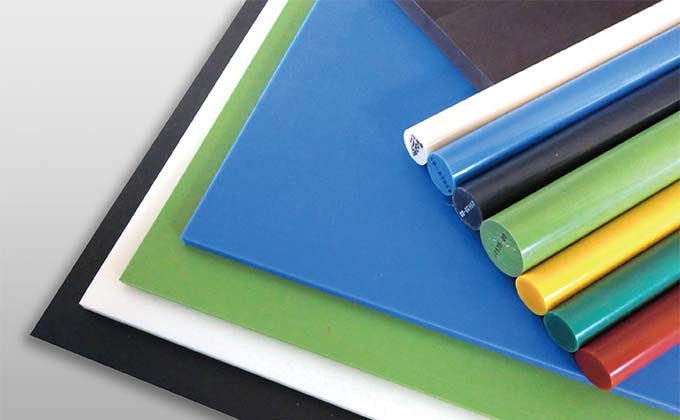

Engineering plastics materials and processed products

Q

Is it possible to manufacture products in non-standard sizes?

A

We also accept orders outside of product standards. Please contact us for details.

Q

Can I also purchase products that are already processed instead of material?

A

We can also handle processed products. We accept orders for as little as one part. We can also handle materials that are not in our lineup, so please feel free to contact us.

Q

We are sometimes asked for a harder resin than POM.

What materials are available?

A

The term "hardness" is often used to refer to the specific properties required. For example, if you want to reduce wear of a part, you can change to a material with higher wear resistance (sliding grade, etc.).

If you want to reduce deformation of the part, you can use a material with higher mechanical strength (e.g., nylon).

Please feel free to contact us first to find out why you need a "hard" resin and what problems you are experiencing.

Q

Are there any resin materials that do not absorb water?

A

Teflon and ultra-high molecular weight polyethylene fall into this category. (Water absorption is less than 0.01%.)

Polyacetal resin also does not absorb water to zero, but dimensional changes do not occur within normal tolerances.

Q

Are there any precautions in handling Cast-Nylon?

A

Since the material absorbs water, care should be taken when using it in places with high humidity or where it is exposed to water. Water absorption may cause slight dimensional changes and degradation of physical properties.

In addition, the material generally has high chemical resistance, but is weak against acids. For details, please refer to our general catalog.

Q

What is the maximum size of Cast-Nylon?

A

Round bars up to φ600 and plates up to 150t can be handled.

Q

Does Cast-Nylon (CN) mean MC nylon?

A

Our cast nylon is generally a "monomer cast nylon" material.

MC Nylon" is a widely known trade name under the trademark of Mitsubishi Chemical Advanced Materials Corporation.

MC nylon" is often used to refer to monomer-cast nylons in general.

Q

Cast-Nylon(MC nylon) is

Is it classified as 6 nylon or 66 nylon?

A

6 nylon. Cast nylon is cast molded by pouring the raw material into a mold and polymerizing it. Cast nylon has higher mechanical strength and lower water absorbency than extruded 6 nylon.

Q

What is the difference between homopolymers and copolymers of POM?

A

The molecular structures are different. As a result, homopolymer (Delrin) has superior mechanical strength to copolymer (Duracon).

On the other hand, copolymer (DURACON) has better chemical resistance and heat aging properties than homopolymer (DURACON).

Q

I'm looking for a material that is resistant to friction and wear.

There are many grades and I don't know which one to choose.

A

Even if we speak of "friction and wear resistance" in general, the specific characteristics required often differ.

For example, if you want to suppress the generation of abrasion powder through use, use a material with high abrasion resistance (such as polyethylene).

If you want to use the product at high surface pressure and high speed, you can change to a material with a higher allowable PV value (sliding grade, etc.).

Please feel free to contact us first to find out what kind of application requires a "friction and wear resistant" resin, and what kind of problems you are experiencing.

Q

What are the characteristics of white, blue, and green ultra-high molecular weight polyethylene?

A

We offer a variety of color shades for use in a wide range of applications. All are standard grades and have the same physical properties.