Technical Library

Premature timing belt failure and troubleshooting

If the timing belt fails prematurely, using it as-is can cause damage to the surrounding parts due to deterioration of functionality or belt breaking, etc.

Premature failure and troubleshooting

Abnormal belt side wear

The side of the belt is damaged due to wear.

| Primary cause | Prevention |

|---|---|

| Poor pulley alignment | Adjust alignment |

| Pulley shafts are not parallel | Correct the parallelism of the pulley shafts. |

| Pulley flange bending | Correct flange bent portion |

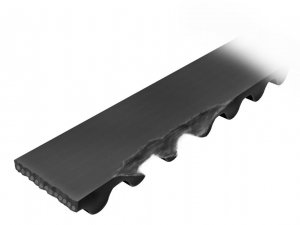

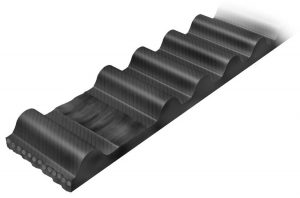

Abnormal wear on pressure-acting surfaces of teeth

Tooth fabric is worn away, exposing rubber and core wire.

| Primary cause | Prevention |

|---|---|

| Overload | Change the design and either increase the belt width or use a belt with a larger tooth pitch. |

| Excessive belt tension or too loose | Adjust the initial tension of the belt |

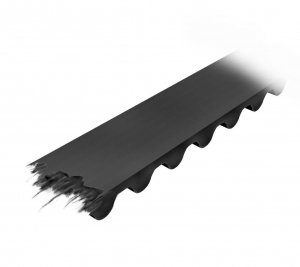

Missing Belt Teeth

Tooth Engagement problems are occurring.

| Primary cause | Prevention |

|---|---|

| Pulley diameter is too small | Change design |

| The number of teeth in mesh with the small pulley is 6 or less | Increase or redesign the number of small pulley meshing teeth |

| Shock-loading is occurring. Heavy shock loading | Widen the belt width |

Belt cord Failure

The belt cord is broken.

| Primary cause | Prevention |

|---|---|

| Overloading | Design changes |

| Decreased elasticity or corrosion of belt cord | Check the storage and transportation status of the belt. |

| Embedding of a foreign object | Install covers around the belt. |

| Used at 80℃ or higher | Reduce ambient temperature |

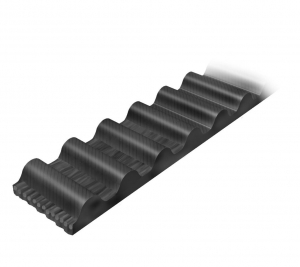

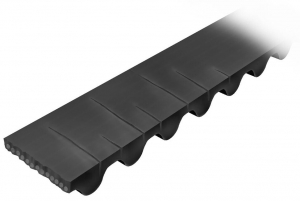

Cracks on back (back rubber)

Cracks in the back rubber of the belt due to increased hardness, etc.

| Primary cause | Prevention |

|---|---|

| Used at ambient temperatures of minus 30℃ or lower | Raise the ambient temperature |

| Pulley diameter is too small | Increase the pulley diameter |

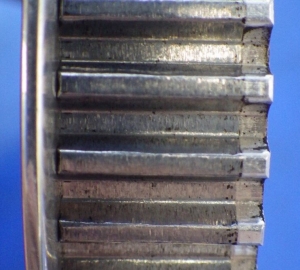

Abnormal wear of pulley teeth

The sides of the pulley teeth are worn.

| Primary cause | Prevention |

|---|---|

| Overloading | Design changes |

| Excessive belt tension | Adjust the initial tension of the belt |

| Pulley material unsuitable (too soft) |

Apply surface treatment or change the material |

※If the pulley has a step of 0.05 mm or more from the belt running point, replace the pulley

【Inspection Method】Measure the step with a dial gauge or measure the tooth thickness with a dial caliper.

Please inspect by measuring the tooth thickness with a dial gauge or dial calipers.

【Inspection Method】Measure the step with a dial gauge or measure the tooth thickness with a dial caliper.

Please inspect by measuring the tooth thickness with a dial gauge or dial calipers.

Pulley outer circumference wear

The tips of the pulley teeth are worn.

| Primary cause | Prevention |

|---|---|

| Life span of pulley | Replace with a new pulley |

| Excessive belt tension | Replace with a new pulleys and belt, and loosen belt tension at the same time. |

※If the pulley is worn 0.05 mm or more than the standard outside diameter (as shown in the catalog), replace the pulley.

【Inspection Method 】Inspect by measuring the outside diameter of the belt running part with a micrometer.

【Inspection Method 】Inspect by measuring the outside diameter of the belt running part with a micrometer.