Environment

Initiatives to Realize a Decarbonized Society

Initiatives to Realize a Decarbonized Society

Measures to reduce CO2 emissions

Considering “contribution to the realization of a decarbonized society” as one of the material issues positioned as important elements in our business activities, we actively work on various measures to reduce CO2 emissions in order to achieve carbon neutrality by 2050 (see the table below).

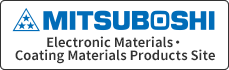

As a result of implementing various measures, CO2 emissions from domestic sites reduced to 28,930 tons*1 in fiscal 2022 (a reduction of 17.3% / 6,049 tons compared to the previous fiscal year; a reduction of 29.2% / 11,948 tons compared to the base year of fiscal 2013). We expect to achieve one of our targets: “a reduction of at least 22% in FY2023 compared to FY2013.”

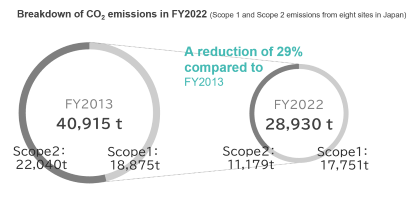

We also calculate not only the Scope 1 and Scope 2 emissions, which are associated with our business activities, but also the Scope 3 emissions, which are indirect emissions other than Scope 2, in order to reduce the environmental impact of the entire supply chain.

For the roadmap for achieving carbon neutrality by 2050,Metrics and targets in this report.

*1 CO2 emissions in Scope 1 and Scope 2 from eight sites in Japan

List of implemented measures to reduce CO2 emissions

|

Period |

Office / Plant |

Measures |

Annual reduction amount / Expected reduction amount*2 |

|---|---|---|---|

|

December 2021 – |

Kobe Head Office / Kobe Plant R&D Center |

Operation of a solar power generation system started |

110t |

| June 2022 – | Kobe Head Office / Kobe Plant R&D Center | Switched to carbon-offset city gas*3 |

(100t) |

| October 2022 – | Kobe Head Office / Kobe Plant R&D Center |

Switched to renewable electricity (all purchased electricity covered) |

1200t |

| October 2022 – |

Suzhou Mitsuboshi Belting Co., Ltd. |

Operation of a solar power generation system started |

900t |

|

July 2022 – |

Shikoku Plant |

|

4,000t |

|

January 2024 Operation scheduled to start |

Shikoku Plant |

|

1,000t |

|

January 2023 – |

Nagoya Plant |

Switched to carbon-offset city gas*3 |

(2,500t) |

|

January 2025 Operation scheduled to start |

Mitsuboshi Belting Giken Co., Ltd. |

Switched to fuel gas for facilities using heavy oil |

2,700t |

|

February 2023 |

(Eight sites in Japan) |

Sustainability linked loan concluded New reduction targets for the interim year (FY2025) established |

- |

※3 Regarding “carbon-offset city gas,” the calculation is made assuming zero contribution to the reduction of CO2 emissions.

Calculation of Scope 3 emissions

We calculated the Scope 3 emissions (calculation using secondary data) to reduce the environmental impact of the entire supply chain.

In the entire supply chain, Scope 1 emissions (direct emissions associated with our own business activities) and Scope 2 emissions (indirect emissions associated with the use of electricity supplied by other companies) together accounted for 17% of total CO2 emissions, with Scope 3 emissions (indirect emissions not included in Scope 1 direct emissions and Scope 2 indirect emissions) accounting for the remaining 83%.

For Scope 3 emissions, CO2 emissions in Category 1 “Purchased goods and services” and Category 11 “Use of sold products” accounted for a high proportion of our Scope 3 emissions. Accordingly, keeping in mind that these emissions will be included in future reduction targets, we will refine the calculation method for Scope 3 emissions, including switching to calculation using primary data, starting with items with a high degree of impact.

Calculation method for Scope 3 emissions

Based on the “Basic Guidelines on Accounting for Greenhouse Gas Emissions throughout the Supply Chain Ver. 2.5” of the Ministry of the Environment and the Ministry of Economy, Trade and Industry, we calculate Scope 3 emissions by multiplying the amount of activity in each category by the relevant emission factor from “[5] Input-output table-based emission factors of the Emissions Intensity Database for Calculating Greenhouse Gas Emissions of Organizations through the Supply Chain Ver. 3.3” issued by the Ministry of the Environment and the Ministry of Economy, Trade and Industry.

Categories 8, 13, 14, and 15 are excluded from the calculation because there are no applicable activities.

CO2 emissions in the 15 categories of Scope 3

|

Category |

Applicable activity |

Scope of activity data used for calculation |

CO2 emissions in FY2022 (tons) |

|---|---|---|---|

| 1 | Purchased goods and services | Non-consolidated |

38,008 |

| 2 | Capital goods | Consolidated | 11,608 |

| 3 | Fuel- and energy-related activities not included in Scope 1 or Scope 2 | Non-consolidated | 5,737 |

| 4 | Upstream transportation and distribution | Consolidated | 4,140 |

| 5 | Waste generated in operations | Non-consolidated | 5,074 |

| 6 | Business travel | Consolidated | 546 |

| 7 | Employee commuting | Non-consolidated | 282 |

| 8 | Upstream leased assets | (Not applicable) | |

| 9 | Downstream transportation and distribution | Consolidated | 248 |

| 10 | Processing of sold products | Consolidated | 8,502 |

| 11 | Use of sold products | Consolidated | 169,443 |

| 12 | End-of-life treatment of sold products | Consolidated | 253 |

| 13 | Downstream leased assets | (Not applicable) | |

| 14 | Franchises | (Not applicable) | |

| 15 | Investments | (Not applicable) | |

| 243,841 |

Energy management

With its roots in “energy conservation” that started with the first oil crisis in 1973, the Mitsuboshi Belting Group's energy management activities have already spanned half a century. At the beginning, concerns about "oil depletion” was the driving force, but cost reduction was added as one of the objectives later. In recent years, energy management has become an important measure and indicator in responding to climate change. We recognize that energy management will lead to the control of global warming and the preservation of biodiversity, and that neither the control of global warming nor the preservation of biodiversity can be achieved unless effective measures are taken immediately. Based on this recognition, we will carry out proactive activities.

Management system

The Mitsuboshi Belting Group conducts energy management in accordance with an environmental management system (EMS) that complies with ISO 14001. The President and the Director in Charge of Safety and the Environment are responsible for the overall management of the EMS and the appointment of a Person with Overall Environmental Responsibility. The Companywide Environmental Conference, with the Person with Overall Environmental Responsibility as chairperson and the responsible persons of all departments and affiliated companies as members, meets twice a year to determine and disseminate policies, strategies, and targets for each fiscal year to all departments and affiliated companies for implementation. The Conference monitors and evaluates the progress of measures implemented at each department and affiliated company, and provides necessary instructions. The Companywide Environmental Conference’s deliberations and decisions are reported to the Management Council and the Board of Directors through the President and the Director in Charge of Safety and the Environment.

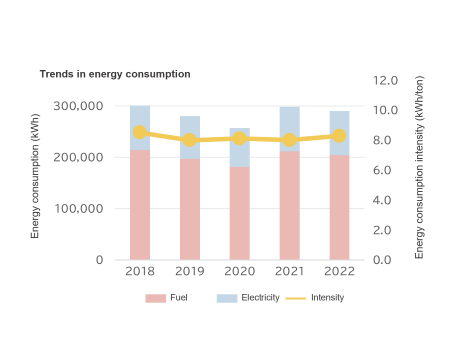

Through discussions at the Sustainability Promotion Committee, which was established in FY2022 to deepen the Mitsuboshi Belting Group's ESG management, we have identified “initiatives for environmental conservation” as a materiality, and “promotion of environmental conservation activities” as an issue to be addressed, and set a KPI target of “reducing energy consumption intensity by 0.5% or more compared to the previous fiscal year.” Energy management activities are therefore subject to monitoring and evaluation by the Sustainability Promotion Committee.

・Sustainability Promotion System

・Materiality

Targets and implementation status

As mentioned above, our target for energy management for FY2022 was to reduce the energy consumption intensity by 0.5% or more compared to the previous fiscal year. However, actual results fell short of the target with an increase of 3.5%. Looking at the trends in energy consumption over the past five years in the chart below, no noticeable effect has been observed. It appears that effective measures have been exhausted over the years of activities. However, when upgrading equipment or improving production methods, design studies are always carried out with energy efficiency in mind. So we believe that energy consumption efficiency has been improving, albeit slightly, but this has been buried in the fluctuations caused by changes in production activities. In 2022, we began the full-fledged introduction of renewable energy aimed at preventing global warming, and 2.95% of energy consumption has been replaced by renewable energy. Since the primary energy equivalent of renewable energy is expected to be smaller than the equivalent of energy derived from fossil fuels, we plan to expand the contribution of renewable energy in our future activities

Measures to reduce CO2 emissions

Strengthening the development of eco-friendly products

Recognizing that it is our corporate social responsibility to promote efforts to resolve environmental issues and realize a decarbonized society, we aim to realize sustainable corporate activities. To this end, we strive to strengthen the development of eco-friendly products and actively work to reduce CO2 emissions in the production process.

Products that contribute to reducing CO2 emissions

TG belts for blade pitch drives in wind power generators

Power transmission belts are used to adjust the pitch of blade angles in wind power generators. We will respond to the expanding demand for wind power generation by developing functions for wind power generators to meet customer requirements in terms of power generation capacity, the installation environment, and other conditions. |

|

|---|---|

Low friction loss belts / TG belts in oil

Low friction loss belts and timing belts in oil, developed for automobile internal combustion engines, are effective in improving fuel economy. By providing power transmission belts with high efficiency and low energy loss, we contribute to reducing exhaust gas and CO2 emissions. |

|

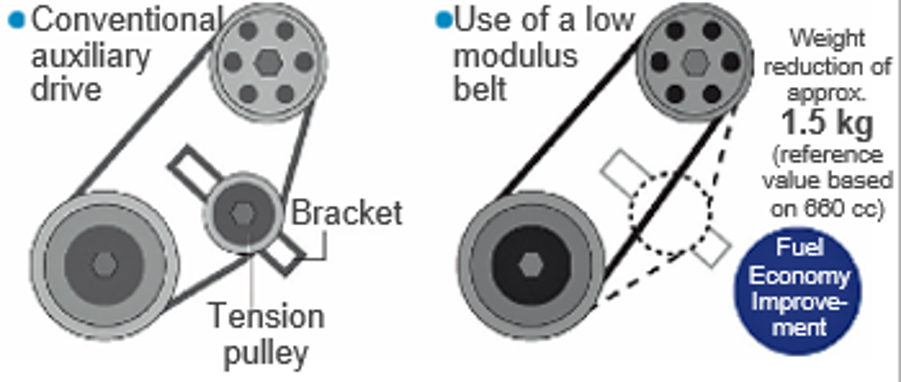

“StarFit™” low modulus belts for automobiles

The adoption of StarFit™ low modulus belts for automobiles eliminates the need to adjust tension. Since no tension pulleys or brackets are required, the system weight is reduced by approximately 1.5 kg, contributing to improved fuel economy. |

|

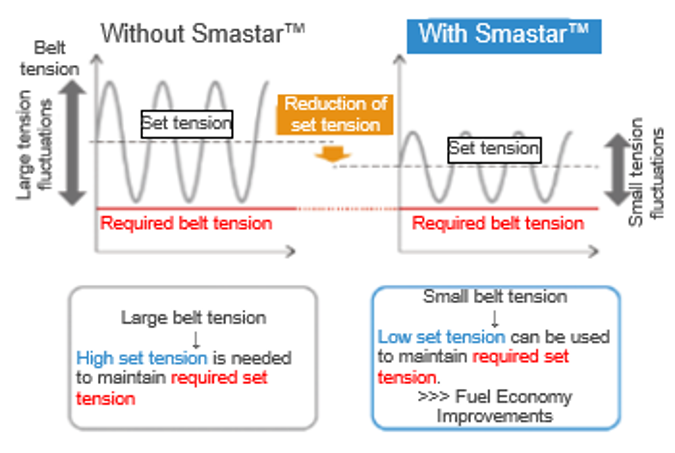

“Smastar™” alternator pulleys for automobiles

Due to fuel economy improvement technologies, such as idling stop,smaller displacement, and direct injection engines, engine rotation fluctuations have become increasingly larger, creating a harsh operating environment for auxiliary belt systems. Smastar™ damper pulleys for alternators, which have been developed to absorb belt tension fluctuations, can reduce the set tension, thereby contributing to suppressing belt pronunciation, improving a belt’s service life, and increasing engine fuel economy. |

|

“e-POWER™” energy-saving belts

The e-POWER™ series comprises eco-friendly belts with a special shape (notch, cog, double cog) that reduces bending stress, which is the largest cause of power loss, and enhances energy-saving effects. Replacing only the conventional belt with e-POWER™ makes it possible to improve power saving for industrial machinery as well as equipment in plants, hospitals, and commercial and office buildings, and reduce CO2 emissions. |

|

Products and production methods that contribute to environmental conservation

“Water-shielding sheets” from the Building & Construction Materials DivisionAs a recycling-oriented society is being built, the amount of waste to be landfilled at final disposal sites is set to decrease to 13 million tons by fiscal 2025 under the leadership of the Ministry of the Environment. Water-shielding sheets, including installation services, provided by the Building & Construction Materials Division are favored for their functionality and reliability in order to prevent contamination of public water areas and groundwater by leachate from final disposal sites. |

|

|---|---|

Contributing to biodiversity conservationThe use of biotopes is promoted at educational institutions across Japan as places for learning, and new ecosystems for animals and plants are created. When a water system is created within the limited school grounds, water-shielding sheets provided by the Building & Construction Materials Division work effectively. We have so far provided water- shielding sheets free of charge to more than 100 educational facilities in Kobe City to cooperate in creating biotopes. |

|